|

|||

|

|

|||

|

Page Title:

Piston Cooling Jets - Remove and Install |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

5. Install the bolts for the engine oil pan. Tighten

the Bolts (X). Tighten the bolts to a torque of

31 3 Nm (23 2 lb ft).

6. Start at Position (Z) and tighten the remaining

bolts in a counterclockwise direction. Tighten

the remaining bolts to a torque of 31 3 Nm

(23 2 lb ft).

7. Start at Position (Z) and tighten the bolts again in

a counterclockwise direction. Tighten the bolts to

a torque of 31 3 Nm (23 2 lb ft).

8. Fill the engine with oil to the correct level. Refer

to the Operation and Maintenance Manual for the

g00610550

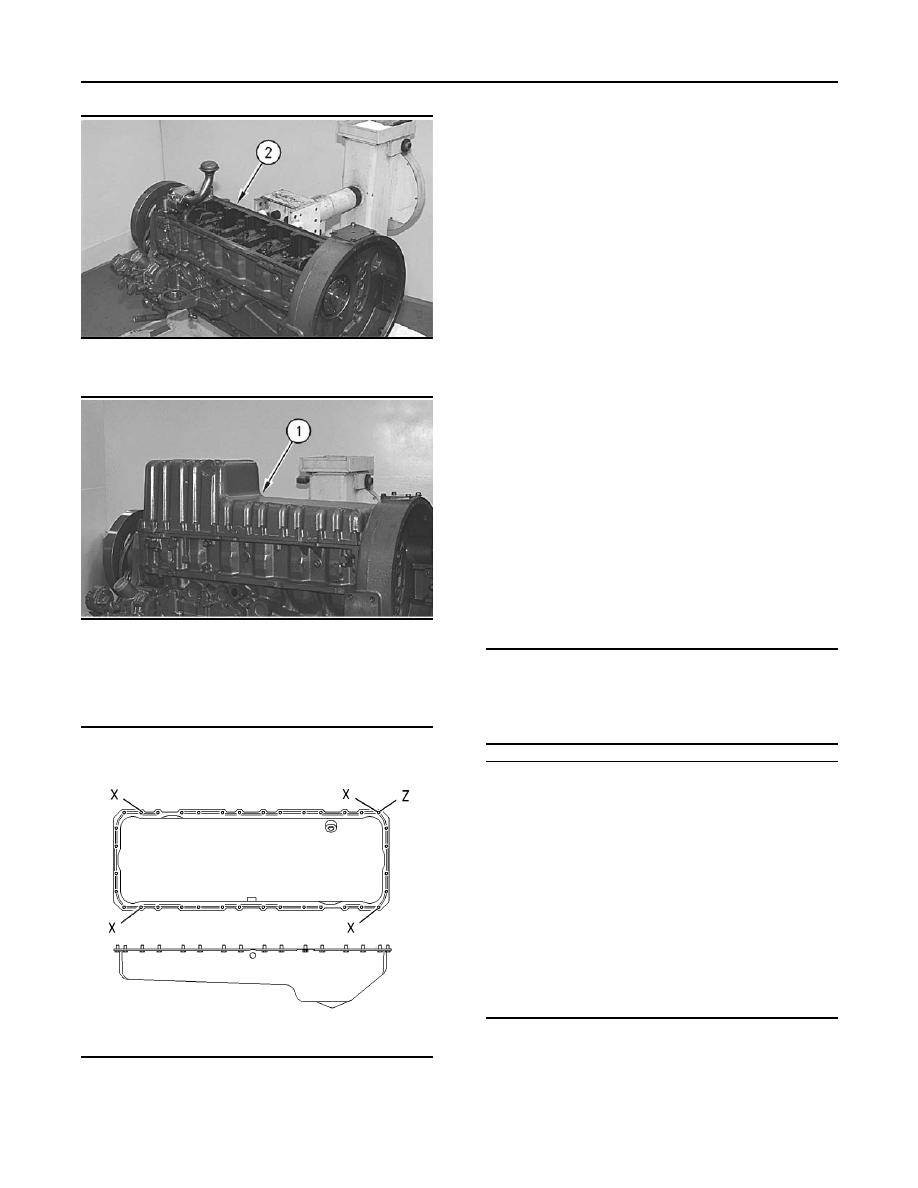

Illustration 207

correct filling procedure.

Typical example

i01150877

Piston Cooling Jets - Remove

and Install

SMCS Code: 1331-010

Removal Procedure

Start By:

a. Remove the engine oil pump. Refer to

Disassembly and Assembly, "Engine Oil Pump -

Remove".

g00610543

Illustration 208

Typical example

NOTICE

Keep all parts clean from contaminants.

4. Place new gasket (2) and engine oil pan (1) on

the cylinder block.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar

Tools and Shop Products Guide" for tools and supplies

suitable to collect and contain fluids on Caterpillar

products.

Dispose of all fluids according to local regulations and

mandates.

g00610574

Illustration 209

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |