|

|||

|

|

|||

|

Page Title:

Illustration 131 Typical example |

|

||

| ||||||||||

|

|

50

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: Replacement rear seals are supplied with a

wear sleeve. This wear sleeve must be installed

with the rear seal. New engines from the factory do

not have a wear sleeve. Do not install the rear seal

if any of the following conditions exist:

The crankshaft rear seal has been separated

g00614109

from the wear sleeve.

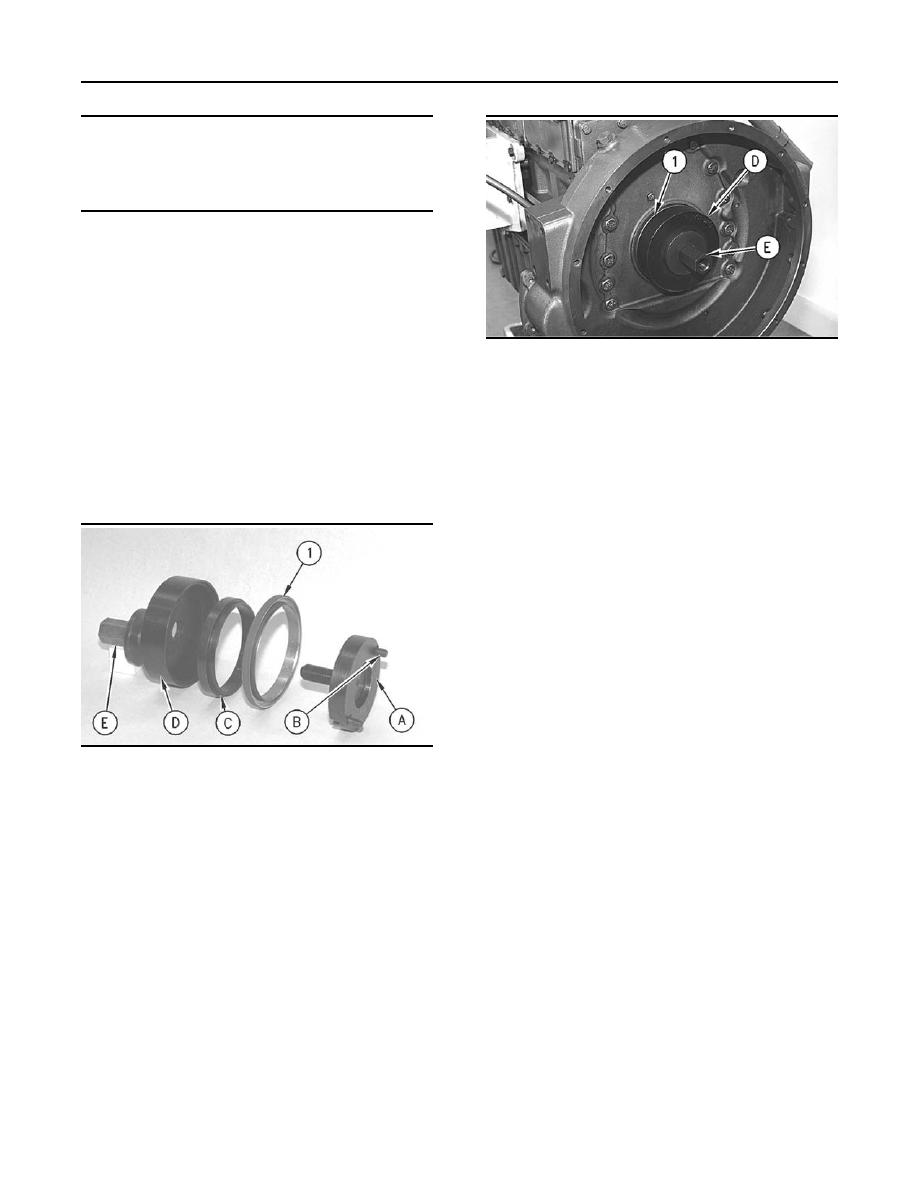

Illustration 131

Typical example

The rear seal group appears to be damaged.

4. Position Tooling (D) over Tooling (A) and Tooling

The crankshaft rear seal has been lubricated. The

(C). Install Tooling (E). Tighten Tooling (E) in

seal is designed to be installed dry.

order to install the crankshaft rear seal and the

crankshaft wear sleeve.

1. Ensure that the rear of the crankshaft is

thoroughly clean and dry prior to the installation

5. Remove Tooling (E), Tooling (D), and Tooling (C).

of the crankshaft rear seal.

Turn over Tooling (C). Install Tooling (C), Tooling

(D), and Tooling (E). Tighten Tooling (E) in order

to complete the installation of the crankshaft rear

seal and the crankshaft wear sleeve.

6. Remove Tooling (E) and Tooling (D). Check

Tooling (C) and Tooling (A). The faces of Tooling

(C) and Tooling (A) will be flush if the crankshaft

rear seal and the crankshaft wear sleeve are

properly installed. Refer to the Specifications

module for more information.

7. Remove Tooling (C), Tool (B), and Tooling (A).

End By:

g00613561

Illustration 130

a. Install the flywheel. Refer to Disassembly and

Assembly, "Flywheel - Install".

2. Fasten Tooling (A) to the rear of the crankshaft

with Tooling (B). Hand tighten Tooling (B).

3. Position the crankshaft rear seal and crankshaft

rear sleeve (1) on Tooling (A). Position Tooling

(C) on Tooling (A).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |