|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Troubleshooting Section

Calibration Procedures

Test Step 1. Install the 7X-1171

Transducer Adapter

A. Turn the ignition key switch to the OFF position.

i01725180

Engine Speed/Timing Sensor -

Calibrate

or right front face of the flywheel housing.

C. Install the 7X-1171 Transducer Adapter into the

SMCS Code: 1912-524

hole for the plug.

System Operation Description:

Results:

Use this procedure under the following situation:

OK Proceed to Test Step 2.

Use this procedure if any of the following conditions

Test Step 2. Install the 6V-2197 Magnetic

exist:

Transducer on the Engine.

22-13 Check Timing Sensor Calibration (42)

A. Put a 2D-6392 O-Ring Seal on the end of the

magnetic transducer.

A timing calibration must be performed under the

following conditions:

Note: A small amount of clean engine oil will allow

the seal to slide onto the transducer more easily.

The ECM requires replacement and the ECM

will not communicate with Caterpillar Electronic

B. Push the magnetic transducer through the

Technician (Cat ET) in order to allow the timing

adapter until the magnetic transducer comes in

calibration to be copied when the "Copy

contact with the outermost portion of the flywheel

Configuration-ECM Replacement" feature is used.

timing calibration ring. Move the O-ring seal

downward against the adapter.

Work has been performed on the engine drive

train (front).

C. Withdraw the magnetic transducer 1.0 mm

(0.04 inch) and hand tighten the nut on the

Note: The timing calibration will not increase the

adapter sleeve in order to secure the magnetic

available engine power or the timing calibration will

transducer in place.

not decrease the available engine power. Do not

expect an increase in power due to the performance

D. Check that the probe is properly installed and

of the timing calibration.

snug. The probe should not move when the

engine is started.

Replacement ECM

E. Connect the 6V-2197 Magnetic Transducer to

If a replacement ECM is required, the ECM

the 7X-1695 Cable.

parameters and the timing calibration can

be transferred from the suspect ECM to the

F. Remove the access cover from the J400 engine

replacement ECM. Timing calibration will NOT be

timing calibration connector.

necessary. This feature requires Cat ET and this

feature is only possible if the existing ECM can

Note: Some engines do not have a J400 engine

communicate with Cat ET.

timing calibration connector in the engine harness.

A 170-3519 Harness is required. Refer to Special

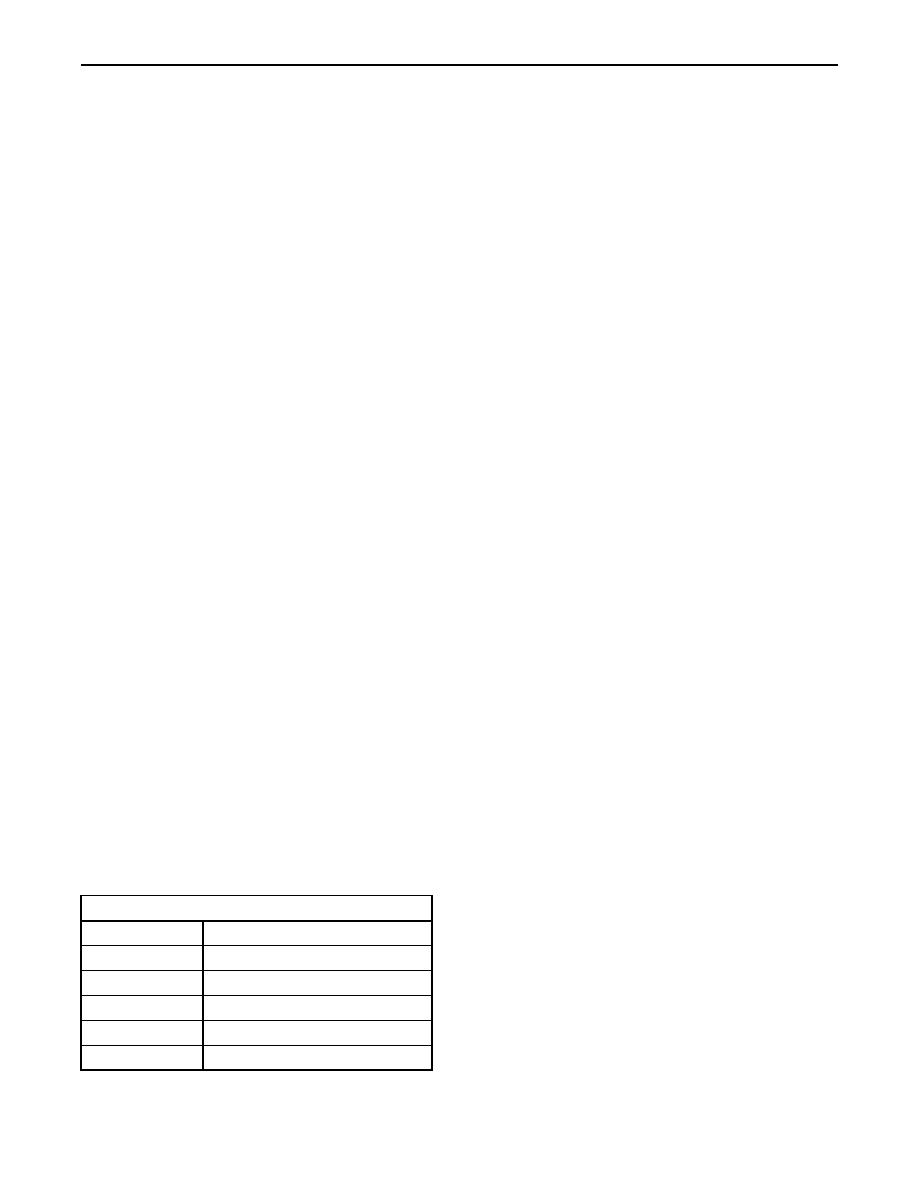

Table 203

Instruction, REHS0399, "Installation Of The 170-3519

Required Special Tools

Timing Calibration Harness Assembly On The

3126B Truck Engine" for the installation procedure.

Part Number

Description

6V-2197

Magnetic Transducer

Results:

7X-1695

Cable

OK Proceed to Test Step 3.

7X-1111

Grommet

9S-9082

Engine Turning Tool

170-3519

Harness

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |