|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Troubleshooting Section

Test Step 3. Use ET to Check the ECM.

Results:

Yes The ECM is OK. The problem is in the

vehicle wiring. Inspect the vehicle wiring and then

repair the vehicle wiring. Otherwise, send the

vehicle to the OEM dealer for repair. Verify that

the original condition is resolved. STOP.

No Temporarily connect a test ECM. Use the

"Starting Aid Output Special Test" on ET to check

the ECM. If the problem is resolved with the test

ECM, install the suspect ECM. If the problem

returns with the suspect ECM, replace the ECM.

Verify that the repair eliminates the problem.

STOP.

i01858198

Tachometer Circuit - Test

SMCS Code: 7462-081

g00838135

System Operation Description:

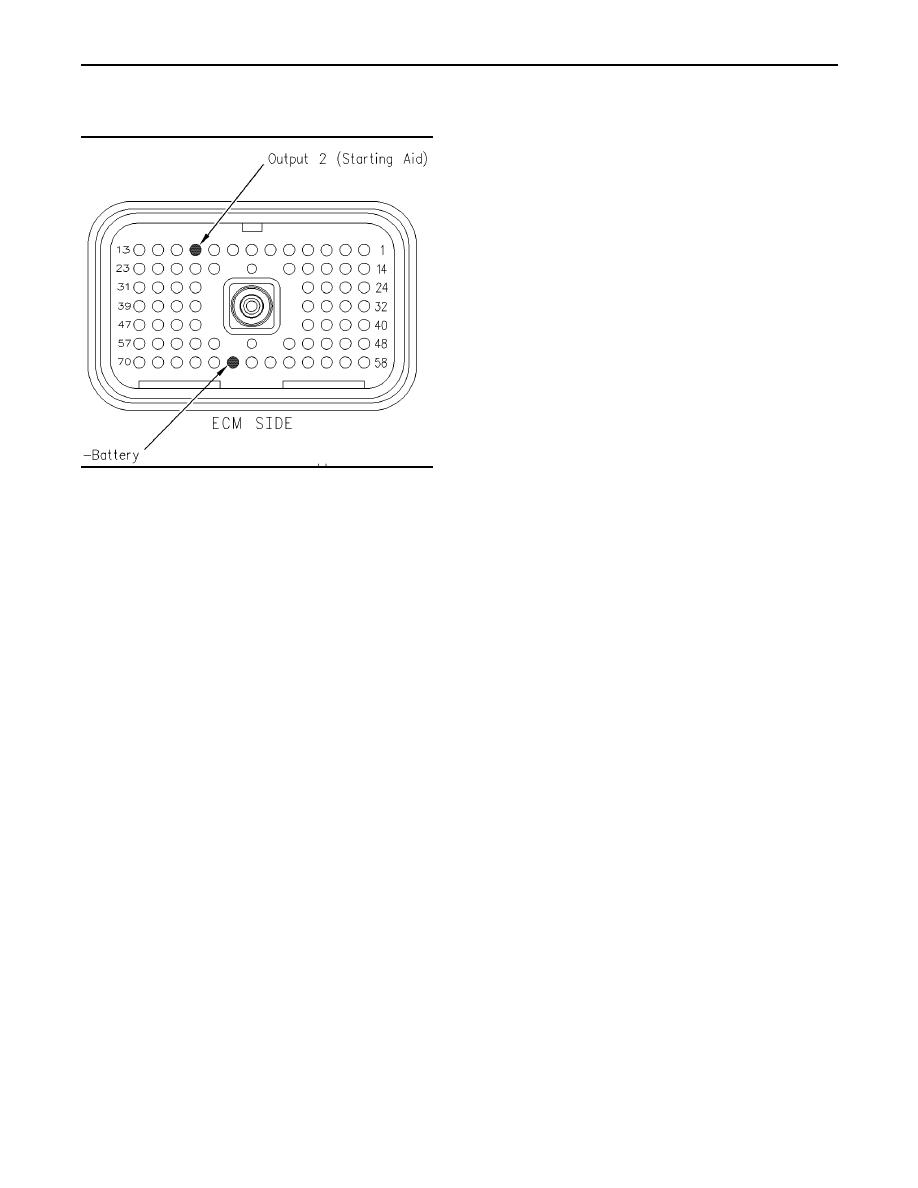

Illustration 173

Breakout T

Use this procedure under the following situation:

A. Connect ET to the cab data link connector.

Use this procedure when all of the following

conditions exist:

B. Turn the ignition key switch to the OFF position.

The ECM is connected to the tachometer.

C. Disconnect the ECM vehicle harness connector

J1/P1.

A problem is suspected.

D. Connect a breakout T between ECM

If the vehicle tachometer is driven by the ECM the

connectorsJ1 and P1.

vehicle tachometer will be connected to the ECM

through connector J1/P1:38 and/or J1/P1:39. Some

E. Connect a voltage test lamp to terminal 10

tachometers require only one of the ECM tachometer

(output 2) and terminal 65 (-battery) of the

signal lines to operate while other tachometers may

breakout T.

require both of the ECM tachometer signal lines to

operate.

F. Turn the ignition key switch to the ON position.

The following background information is related

G. Access the special test "Starting Aid Output" on

to this procedure:

ET.

The tachometer circuit consists of the tachometer

H. Cycle the special test "Starting Aid Output"

that is connected to the ECM through connector

to "Active" and to "Not Active" and watch the

J1/P1 and associated wiring. The ECM engine

voltage test lamp.

speed signal is provided by the crankshaft position

sensor. The ECM converts the signal from the

I. Stop the special test.

crankshaft position sensor into engine rpm in pulses

per revolution before the ECM sends a signal to

Note: A multimeter can not be used in place of the

the tachometer. The selection of the pulses per

voltage test lamp when the ECM outputs are being

revolution for the tachometer is done through the

tested.

Customer Programmable Parameter "Tachometer

Expected Result:

The ECM tachometer signal is programmable

The voltage test lamp turns ON when the test is

from 12.0 to 500.0 pulses per revolution in 0.1

active. The voltage test lamp turns OFF when the

increments. The tachometer must be calibrated

test is not active.

identically to this value for proper operation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |