|

|||

|

|

|||

|

Page Title:

Powertrain Data Link Circuit - Test |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Troubleshooting Section

Test Step 7. Insert a Jumper at the

Inspect the vehicle wiring and repair the vehicle

Bulkhead Connector.

wiring, as required. If the problem still exists with

the wiring, send the vehicle to the OEM dealer.

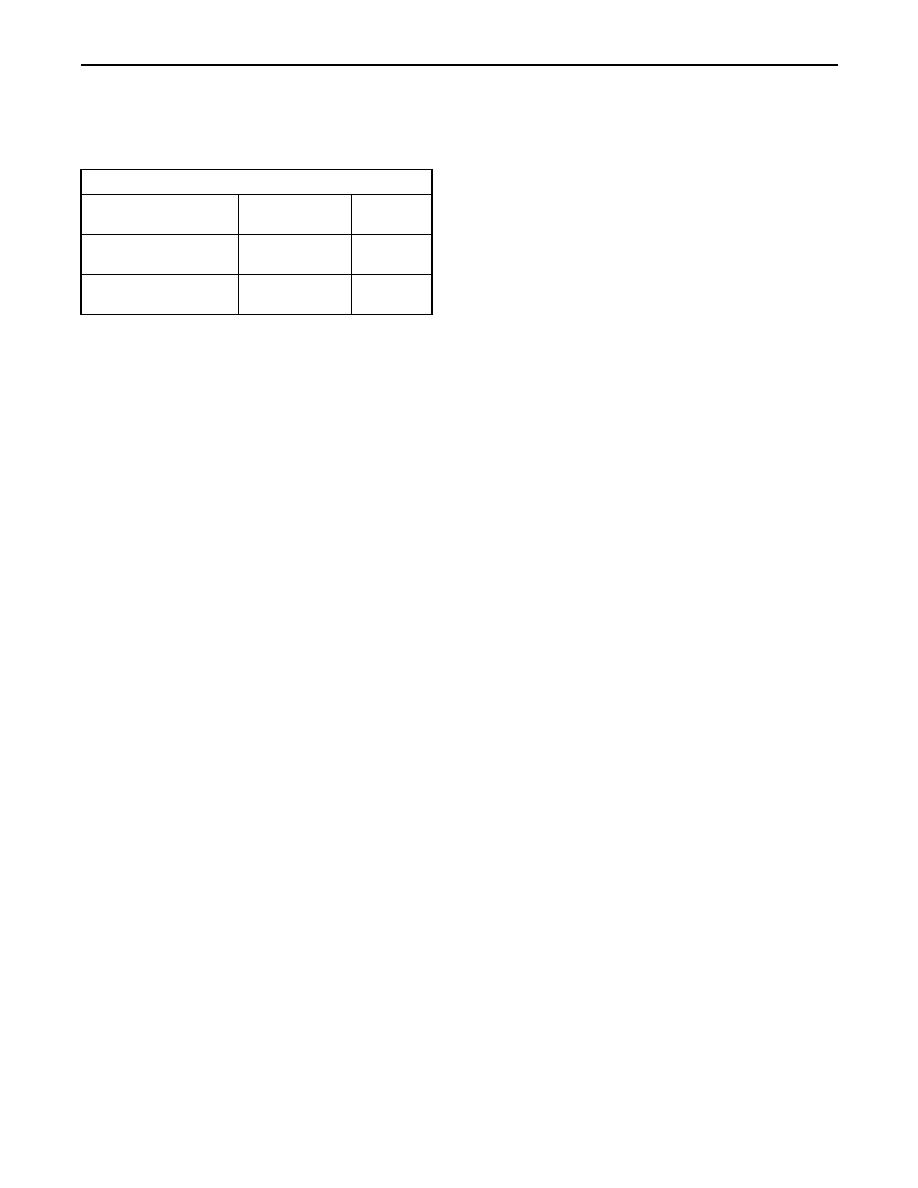

Table 182

STOP.

Neutral Switch Input Status Table

Condition of Switch

Switch Status

Circuit

Circuit

i01858020

Powertrain Data Link Circuit -

Bulkhead wires are

OFF in gear

Open

disconnected.

Test

Bulkhead wires are

ON in neutral

Shorted

connected.

SMCS Code: 1900-081

System Operation Description:

A. Turn the ignition key switch to the OFF position.

Use this procedure under the following situation:

B. Fabricate a jumper wire 100 mm (4 inch) long.

Crimp a Deutsch pin to both ends of the wires.

Use this procedure if one of the following diagnostic

codes are active:

C. Find the neutral switch terminal and the +battery

connection in the engine side of the bulkhead

231-02 J1939 Required Data Not Received (58)

connector for the vehicle harness.

231-11 J1939 Data Link Fault (58)

D. Insert the jumper wire between the two terminals

in the engine side of the bulkhead connector.

231-12 J1939 Device Not Responding (58)

E. Turn the ignition key switch to the ON position.

Also, use this procedure when ET indicates that the

sensor and the ECM are functioning but the engine

F. Connect ET to the cab data link connector.

is not responding to the accelerator pedal position

sensor.

G. Access the status screen.

The following background information is related

H. While the switch status is being monitored on the

to this procedure:

status screen alternately remove the jumper wire

between the two terminals, and alternately insert

Power train Data Link

the jumper wire between the two terminals.

The power train data link is designed to offer

Refer to Table 182.

electronically controlled Anti-Lock Brakes (ABS),

traction control systems, and/or transmission

Expected Result:

controls. This is accomplished by a momentary

reduction of engine rpm and/or engine torque, that

The switch status changes per the information in

is triggered by a signal from an off-engine control

Table 182.

module for the ABS, the traction control, or the

transmission. An off-engine control module is a

Results:

control module that is not part of the Caterpillar

engine control system.

Yes The problem is in the vehicle wiring

between the bulkhead connector and the switch.

With OCT01 and newer Personality Modules,

information from switches may also be transmitted

Repair: Perform the following repair:

over the J1939 data link. The following parameters

can be programmed to send switch information

Inspect the vehicle wiring and repair the vehicle

over the J1939 data link:

wiring, as required. If the problem still exists with

the wiring, send the vehicle to the OEM dealer.

"Cruise Control On/Off Switch"

STOP.

"Cruise Control Set/Resume Switch"

No The problem is in the vehicle wiring between

"Cruise Pause Switch"

the bulkhead connector and the ECM.

"Service Brake Pedal Position Switch #1"

Repair: Perform the following repair:

"Clutch Pedal Position Switch"

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |