|

|||

|

|

|||

|

Page Title:

Test Step 1. Use the Electronic service Tool to Check for Active Diagnostic Codes |

|

||

| ||||||||||

|

|

305

TM 9-2320-312-24-2

Troubleshooting Section

g00724865

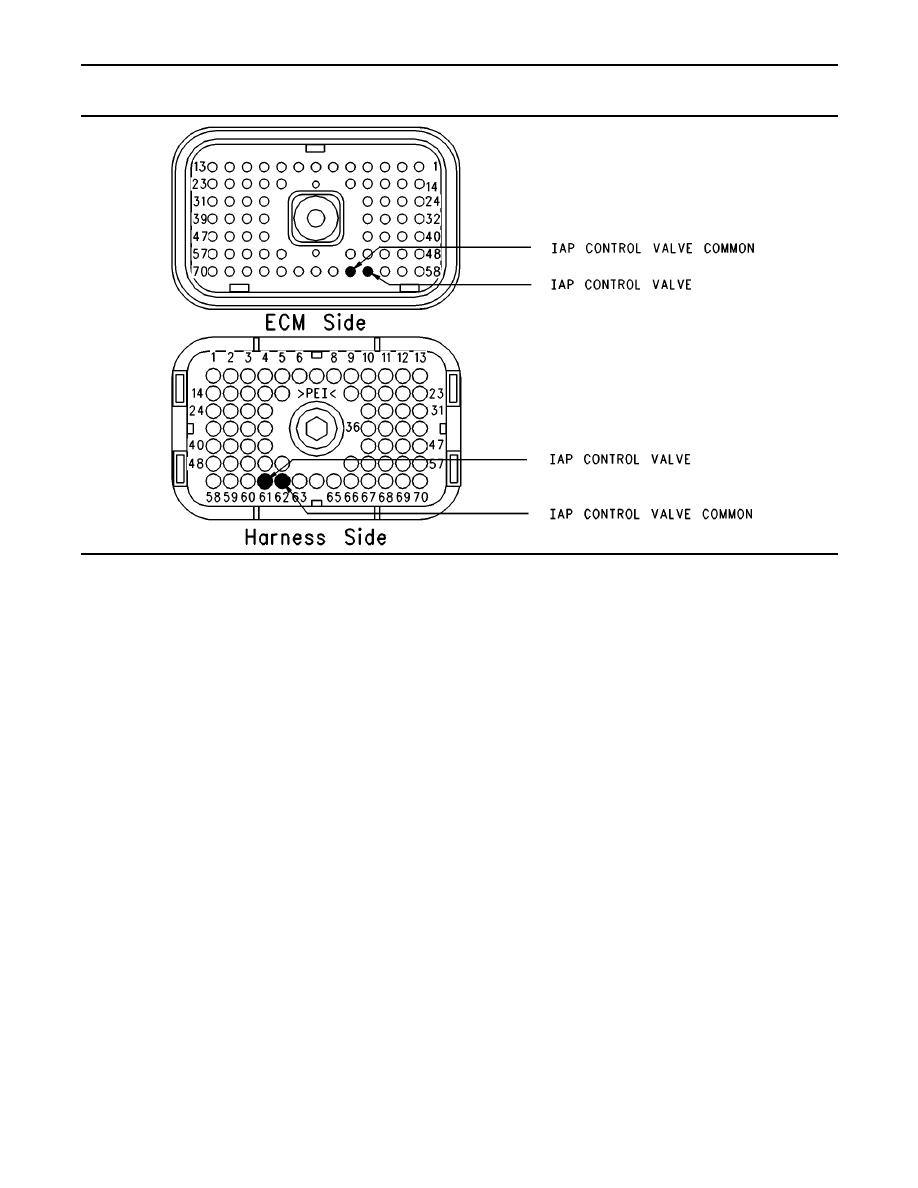

Illustration 128

Locations for the ECM terminals

Test Step 1. Use the Electronic service

Test Step 2. Inspect Electrical Connectors

and Wiring.

Tool to Check for Active Diagnostic

Codes.

A. Thoroughly inspect the connector J500/P500 for

the injection actuation pressure control valve

A. Connect the electronic service tool to the cab

and inspect the ECM engine harness connector

data link connector.

J2/P2. Refer to Troubleshooting, "Electrical

Connectors - Inspect" for details.

B. Start the Engine.

B. Perform a 45 N (10 lb) pull test on each of the

C. Monitor the "Active Diagnostic Code" screen on

wires in the ECM connector that are associated

the electronic service tool. Check and record

with the injection actuation pressure sensor

active diagnostic codes.

(terminals 61 and terminal 62).

Note: Wait at least 15 seconds in order for the

C. Check the ECM connector (allen head screw) for

diagnostic codes to become active.

the proper torque of 6.0 Nm (55 lb in).

Expected Result:

D. Check the harness and wiring for abrasion and

pinch points from the sensors back to the ECM.

42-11 Injection Actuation Pressure Valve Driver is

active.

Expected Result:

Results:

All connectors, pins and sockets should be

completely coupled and/or inserted and the harness

Yes Proceed to Test Step 2.

and wiring should be free of corrosion, abrasion

or pinch points.

No

Results:

Repair: Refer to Troubleshooting, "Troubleshooting

Without a Diagnostic Code".

OK Proceed to Test Step 3.

STOP.

Not OK

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |