|

|||

|

|

|||

|

Page Title:

Test Step 6. Check Connectors for Moisture or Corrosion |

|

||

| ||||||||||

|

|

241

TM 9-2320-312-24-2

Troubleshooting Section

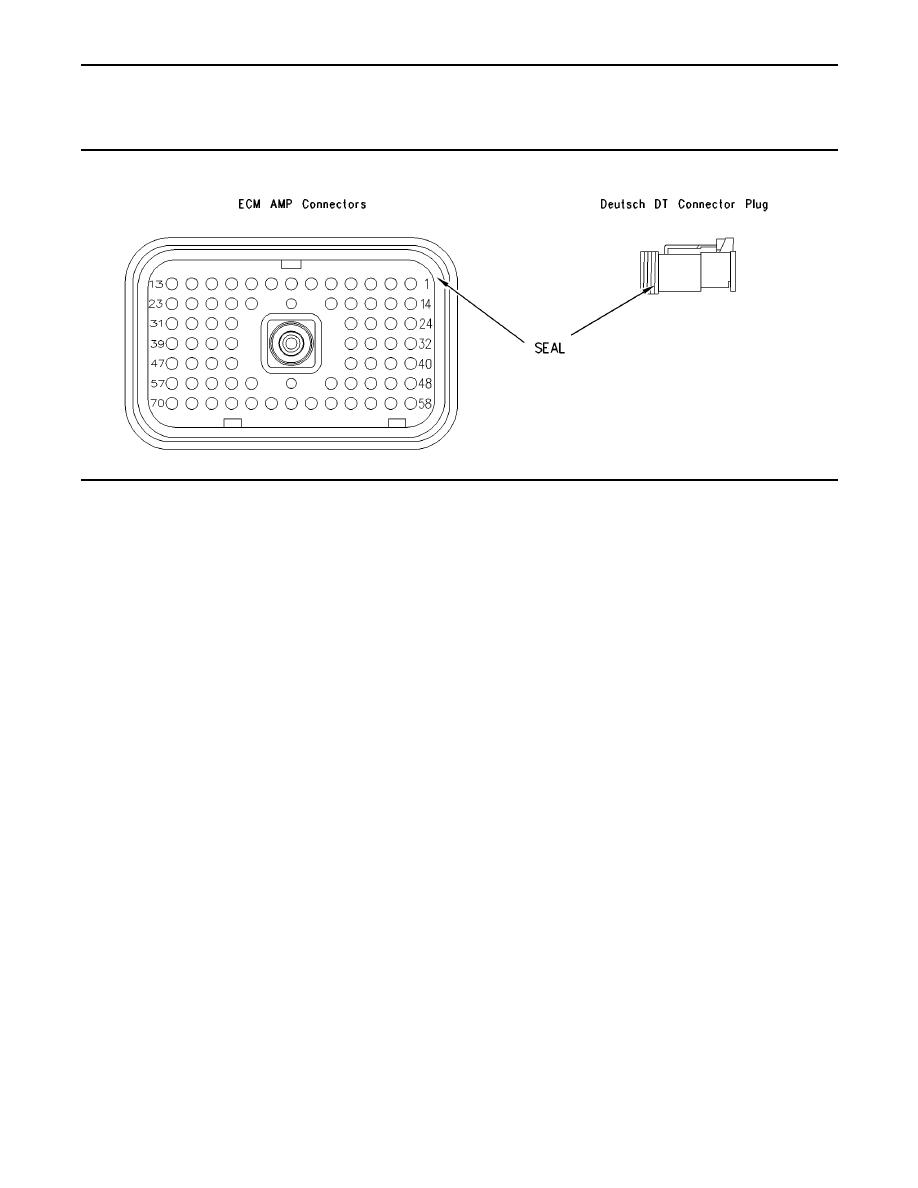

Test Step 6. Check Connectors for

Moisture or Corrosion

g00705443

Illustration 80

Connector seals

Moisture can also travel from one connector

A. Ensure that the connector seals and the white

through the inside of a wire to the ECM

sealing plugs are in place. If any of the seals or

Connector. If moisture is found in the ECM

plugs are missing, replace the seal or plug. If

connector, thoroughly check all connectors and

necessary, replace the connector.

wires on the harness that connect to the ECM.

The ECM is not the source of the moisture. Do

B. Check all of the wiring harnesses in order to

not replace an ECM if moisture is found in either

verify that the harness does not make a sharp

ECM connector.

bend out of a connector. This will deform the

connector seal and this will create a path for the

Note: If corrosion is evident on the pins, sockets or

entrance of moisture.

the connector, use only denatured alcohol to remove

the corrosion. Use a cotton swab or a soft brush

Thoroughly inspect the J1/P1 and J2/P2 ECM

to remove the corrosion. Do not use any cleaners

connectors for evidence of moisture entry.

that contain 1,1,1 trichloro-ethylene because 1,1,1

trichloro-ethylene may damage the connector.

Note: It is normal to see some minor seal abrasion

on the ECM Connector seals. Minor seal abrasion

will not allow the entry of moisture.

Expected Result:

All of the connectors should be completely coupled

C. If moisture or corrosion is evident in the

and all of the seals should be completely inserted.

connector, the source of the moisture entry

The harness and the wiring should be free of

must be found and the source of the moisture

corrosion, abrasion or pinch points.

entry must be repaired. If the source of the

moisture entry is not repaired, the problem will

reoccur. Simply drying the connector will not fix

Results:

the problem. Likely paths for the entrance of

OK Proceed to Test Step 7.

moisture are illustrated in the following list:

Missing seals

Not OK

Improperly installed seals

Repair: Repair the connectors or wiring and/or

replace the connectors or wiring. Ensure that all

Nicks in exposed insulation

of the seals are properly in place and ensure that

the connectors are completely coupled.

Improperly mated connectors

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |