|

|||

|

|

|||

|

Page Title:

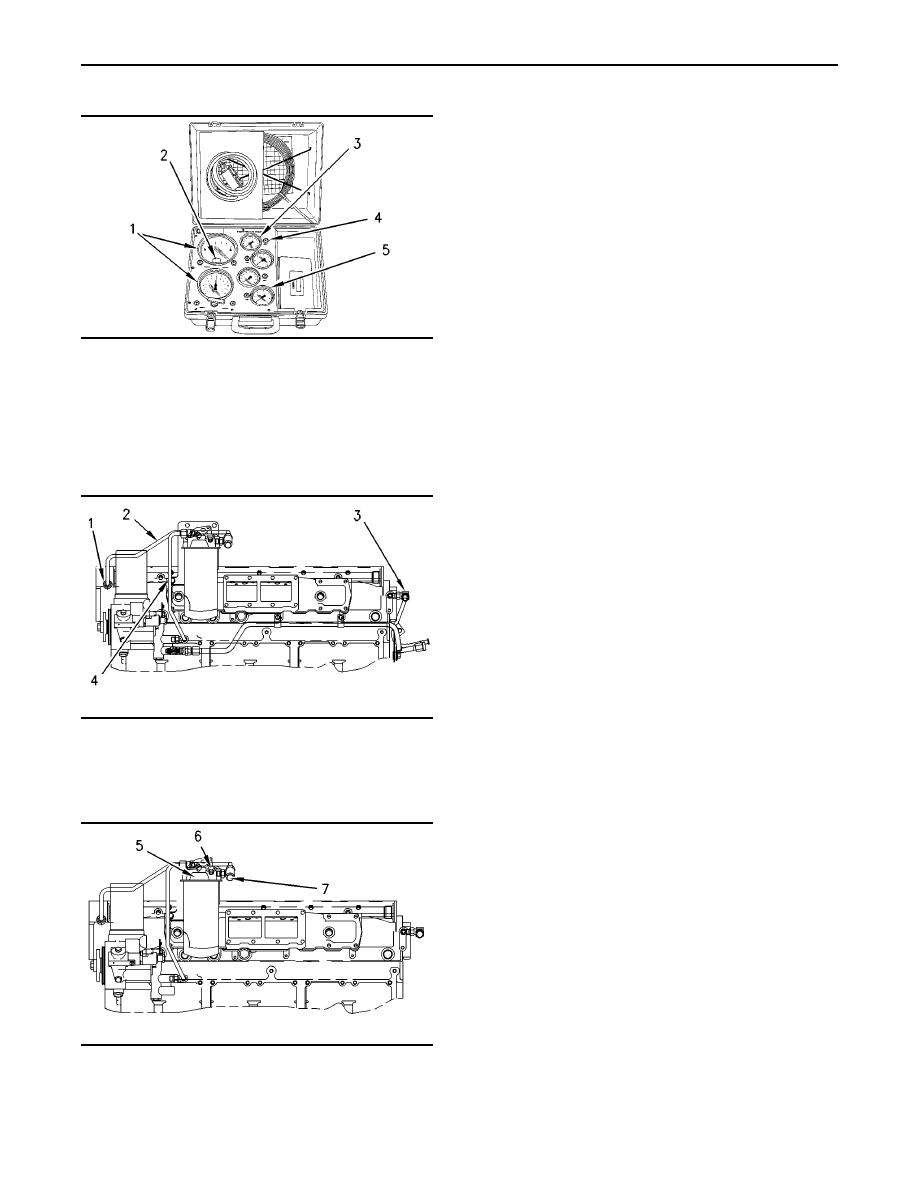

Illustration 48 1U-5470 Engine Pressure Test Group |

|

||

| ||||||||||

|

|

65

TM 9-2320-312-24-2

Testing and Adjusting Section

During both normal operating conditions and load

conditions, the fuel pressure should register the

following range:

400 to 525 kPa (58 to 76 psi)

At low idle, the fuel pressure at the fuel filter's inlet

should be at the following amount:

400 to 435 kPa (58 to 63 psi)

The fuel pressure to fuel supply passage (1) should

be the same amount, if you subtract the change in

pressure (delta P) across the filter.

g00284796

Illustration 48

With a new filter, the pressure drop across the fuel

filter typically registers the following amount:

1U-5470 Engine Pressure Test Group

(1) Pressure indicators. (2) Zero adjustment screw. (3) Pressure

35 kPa (5 psi)

indicator. (4) Pressure tap. (5) Pressure indicator.

This tool group has a gauge that is used to register

As abrasive particles collect in the fuel filter, the

the pressure in the fuel manifolds. The Special

pressure differential across the filter will increase.

Instruction, SEHS8907 is with the tool group.

When a filter becomes plugged, fuel supply

pressure may drop as low as 69 kPa (10 psi)

before a significant power loss is detected by the

operator. Low fuel pressure will cause cavitation

and internal damage to the unit injectors. The

pressure differential across the fuel filter should

not exceed 69 kPa (10 psi).

Pressure regulator (3) is mounted directly in the

cylinder head. The regulator is located at the fuel

return port toward the rear end of the fuel supply

passage (1). The orifice maintains fuel pressure at

low engine rpm.

To check the unfiltered fuel pressure, follow this

procedure:

g00296502

Illustration 49

1. Remove the plug from fuel pressure tap (6).

Fuel Return Line (Typical Example)

(1) Fuel supply passage. (2) Tube assembly (CPU to fuel supply

2. Install the connector, the seal, and the engine

passage). (3) Pressure regulator. (4) Tube assembly (fuel transfer

pump to fuel filter).

pressure test group to fuel pressure tap (6).

This will obtain the fuel transfer pump pressure.

To check the fuel pressure in the fuel supply

passage (1), follow these steps:

1. Remove the plug from fuel pressure tap (7).

2. Install the adapter, the seal, and the engine

pressure test group to fuel pressure tap (7).

3. Operate the engine.

Note: Make sure that the fuel filter is clean before

you check the fuel pressure. A restricted fuel filter

g00296503

Illustration 50

causes lower fuel pressure at fuel pressure tap (7)

Fuel Pressure Test (Typical Example)

than the fuel pressure at fuel pressure tap (6).

(5) Fuel filter base. (6) Fuel pressure tap (unfiltered tap). (7) Fuel

pressure tap (filtered tap).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |