|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Specifications Section

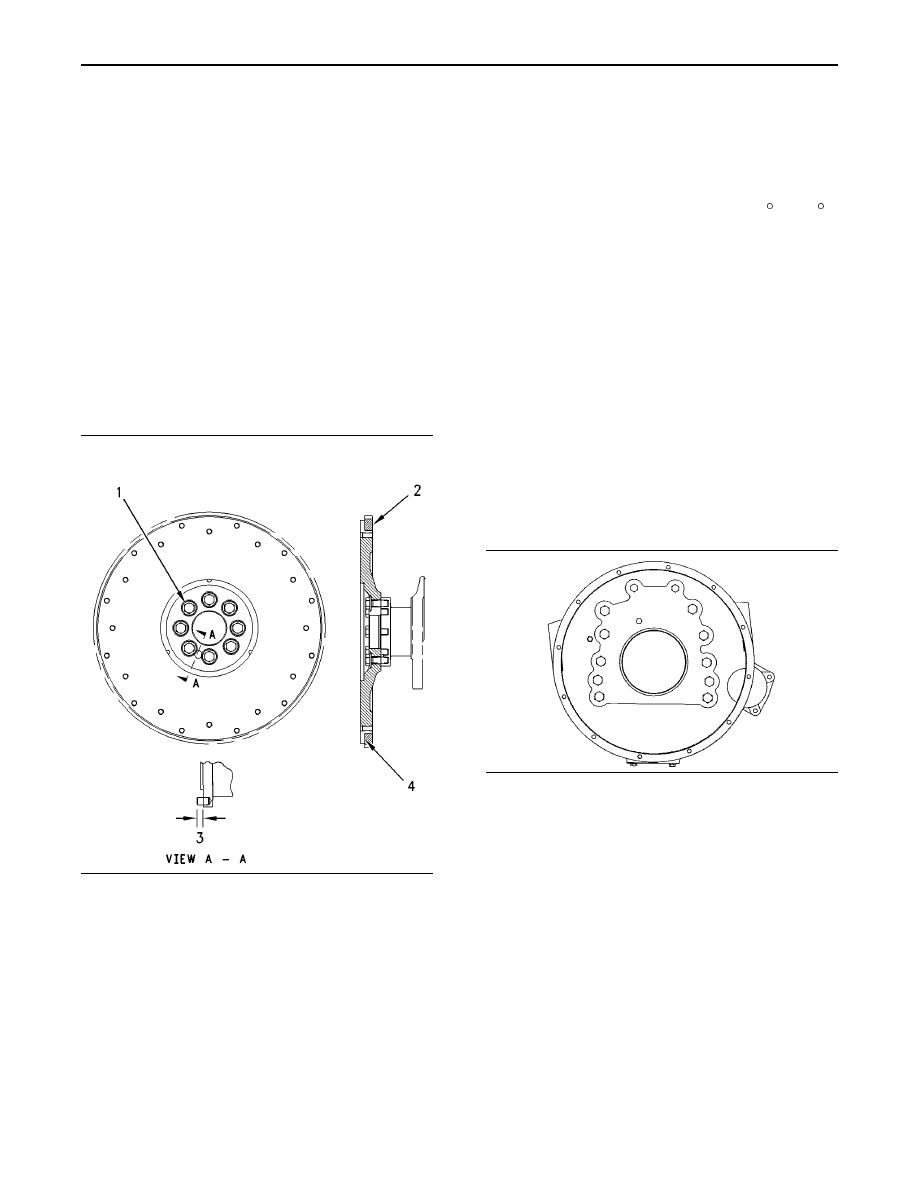

1. Install the flywheel ring gear. Face the "part

(7) Apply 9S-3263 Thread Lock Compound to the

number" on the ring gear (2) toward the engine

threads of the oil pump idler gear bolt. Tighten

block. The flywheel ring gear must be installed

the bolt to the following torque. ..... 70 15 Nm

against the shoulder (4). The flywheel ring gear

(50 11 lb ft)

can be heated for installation. Do not use a torch.

(8) Oil pump idler gear

Maximum temperature ................... 204 C (400 F)

Distance between the rear of the bearing face and

the rear of the gear face (C) ......... 0.75 0.25 mm

2. Press the spring pin (3) into the crankshaft before

(0.030 0.010 inch)

assembling the flywheel to the crankshaft. Check

the distance from the face of the crankshaft to

Diameter of new shaft (D) ........ 28.644 0.013 mm

the end of the pin (3).

(1.1277 0.0005 inch)

Distance ............. 11.0 1.0 mm (.43 .04 inch)

i00672569

3. Tighten the bolts (1) that hold the flywheel to the

Flywheel

crankshaft.

Tighten to the following torque. ..... 120 20 Nm

SMCS Code: 1156

(90 15 lb ft)

i00672686

Flywheel Housing

SMCS Code: 1157

g00293373

Illustration 49

Mounting face for the block

Note: Refer to Systems Operation, Testing and

Adjusting for the correct method of inspecting the

flywheel housing.

g00293319

Illustration 48

Note: Apply 1U-8846 Liquid Gasket to all of the

Note: Refer to System Operation, Testing and

sealing surfaces of the flywheel housing . The

Adjusting for the correct method of inspecting the

flywheel housing must be assembled and tightened

flywheel.

to the block within ten minutes.

(1) Bolt

(2) Ring gear

(3) Spring pin

(4) Shoulder

The following instructions should be used during

installation of the ring gear:

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |