|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Specifications Section

Tighten each of the cap bolts to the following

Note: Handle the fractured connecting rod with

torque. .......................... 54 5 Nm (40 4 lb ft)

care. Use a soft jawed vise in order to hold the

connecting rod while loosening the connecting rod

3. Place an index mark on each connecting rod

cap bolts. Use a soft faced hammer in order to tap

cap bolt and tighten each of the cap bolts for an

the connecting rod cap, if necessary.

additional 60 5 degrees (1/6 of a turn).

The connecting rod small end must be heated from

175 to 260 C (347 to 500 F) before the installation

i01569859

of the piston pin bearing.

Piston and Rings

Apply heat only within length (A) of the connecting

rod. ................................. 75 5 mm (3.0 .2 inch)

SMCS Code: 1214; 1215

The bearing joint for the piston pin bearing (B) must

Two-Piece Articulated Piston

be positioned at 12 5 degrees (C) above the

centerline on either side.

(1) Bore size for the piston pin bearing

Bore in the connecting rod for the piston pin

bearing ............................... 43.191 0.013 mm

(1.7004 0.0005 inch)

(2) Bore size for the piston pin after the installation

of the bearing

Bore in the piston pin

bearing ............................... 40.028 0.008 mm

(1.5759 0.0003 inch)

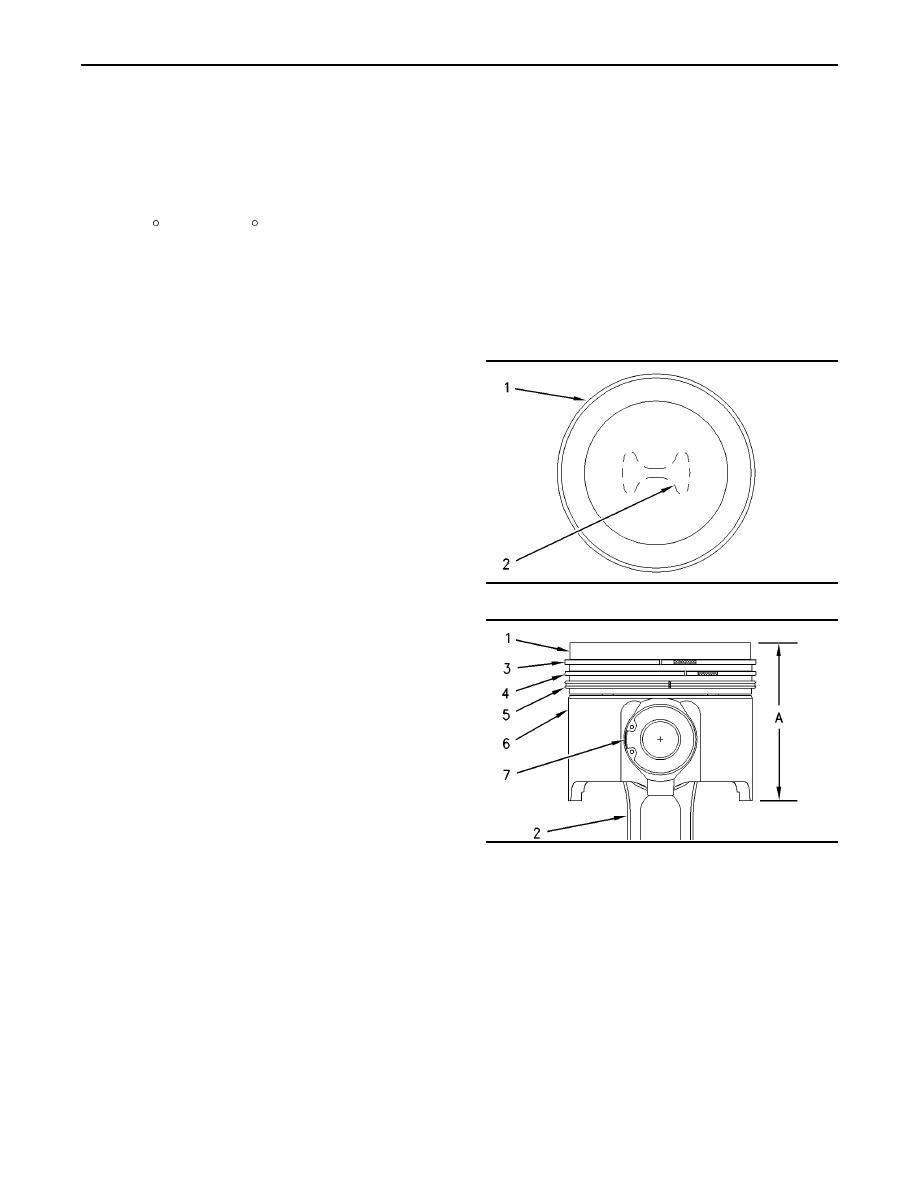

g00293184

(3) Distance between the center of the connecting

Illustration 42

rod bores .............................. 200 mm (7.9 inch)

(4) Crankshaft bore in the connecting rod for

connecting rod journal ....... 75.000 0.013 mm

(2.9527 0.0005 inch)

Note: Use the following procedure to tighten

the connecting rod bolts before measuring the

crankshaft bore. Check the dimensions of the

crankshaft bore only after the tightening procedure

has been followed.

(5) Connecting rod bolts

Use the instructions that follow in order to tighten

g00293185

Illustration 43

the connecting rod cap bolts:

(1) Crown assembly

1. Before installing the rod cap, clean the mating

surfaces of the connecting rod with compressed

(2) Connecting rod

air or a steel brush. Ensure that there are no

loose particles that remain from the process that

Note: Install the rod and piston group in the engine

is used to fracture the rod.

with the part number to the rear of the engine.

The rear of the engine is the flywheel end of the

Note: Lubricate the seating faces of the rod cap

engine. Lubricate the rod and piston group with

bolts with 5P-3931 Anti-Seize Compound or engine

clean engine oil before you insert the rod and piston

oil before installing the bolts.

group into the block.

2. Install new connecting rod cap bolts (5).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |