|

|||

|

|

|||

|

Page Title:

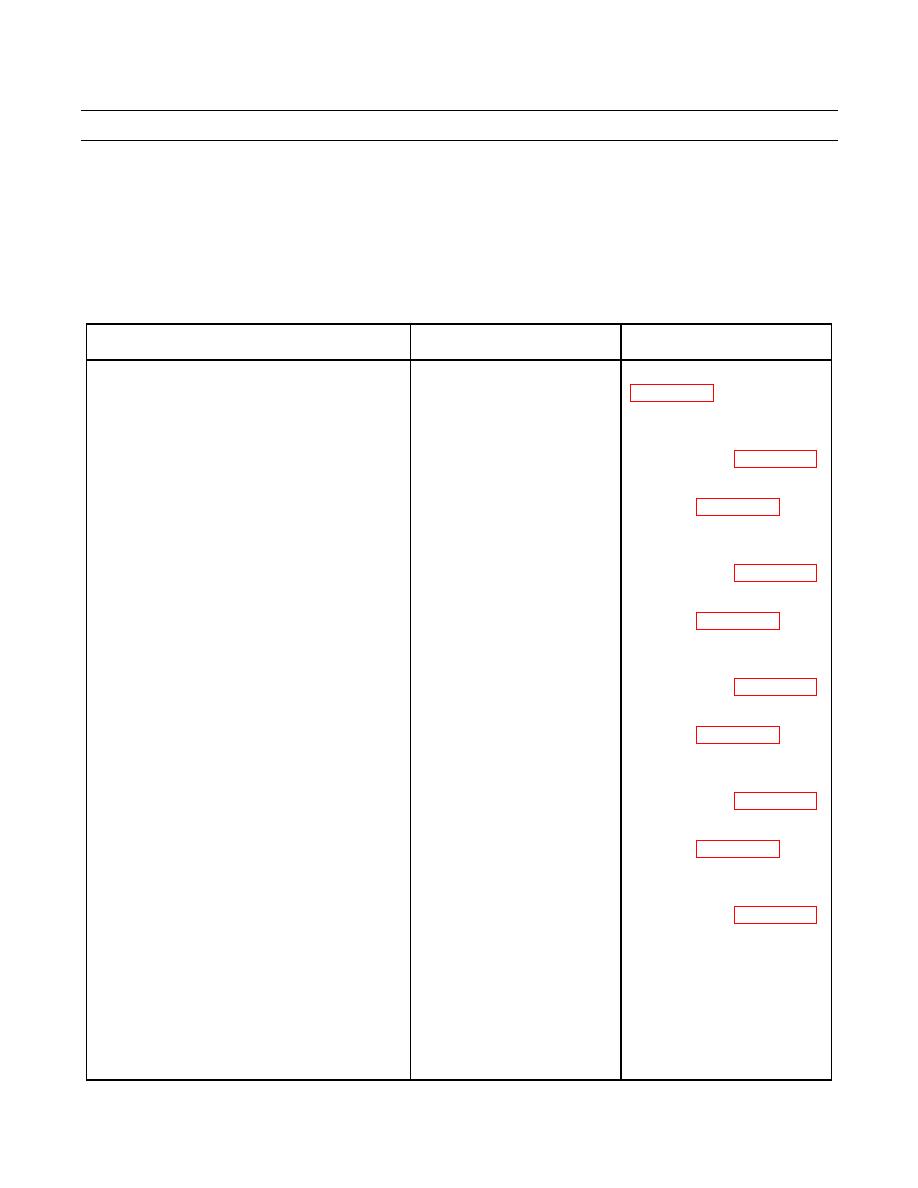

Table 2. Air System Troubleshooting Procedures. |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-1

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

NOTE

For engine air compressor troubleshooting, refer to Group 020 Commercial Service Manuals.

For engine air compressor governor troubleshooting, refer to Group 150 Commercial Service

Manuals.

For air dryer troubleshooting, refer to Group 150 Commercial Service Manuals.

Table 2. Air System Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Dual Air Pressure Gauge Inoperative.

1. Inspect gauge for signs of

Replace dual air pressure gauge

damage.

Tighten leaking lines and/or

2. Inspect air lines and fittings

for leaks and signs of

replace crimped or damaged

crimping or damage.

lines and fittings (WP 0066 00).

2. Fifth Wheel Lock Control Valve Inoperative.

1. Check control valve for free

Replace control valve if frozen

movement.

or binding (WP 0075 00).

Tighten leaking lines and/or

2. Inspect air lines and fittings

for leaks and signs of

replace crimped or damaged

crimping or damage.

lines and fittings (WP 0066 00).

3. Parking Brake Control Valve Inoperative.

1. Check control valve for free

Replace control valve if frozen

movement.

or binding (WP 0072 00).

Tighten leaking lines and/or

2. Inspect air lines and fittings

for leaks and signs of

replace crimped or damaged

crimping or damage.

lines and fittings (WP 0066 00).

4. Trailer Air Supply Control Valve Inoperative.

1. Check control valve for free

Replace control valve if frozen

movement.

or binding (WP 0073 00).

Tighten leaking lines and/or

2. Inspect air lines and fittings

for leaks and signs of

replace crimped or damaged

crimping or damage.

lines and fittings (WP 0066 00).

5. Trailer Brake Control Valve Inoperative.

1. Check control valve for free

Replace control valve if frozen

movement.

or binding (WP 0074 00).

Tighten leaking lines and/or

2. Inspect air lines and fittings

for leaks and signs of

replace crimped or damaged

crimping or damage.

lines and fittings (WP 0066 00).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |