|

| |

TM 9-2320-304-14&P

5-142.6

Organizational Maintenance Instructions (Cont)

5-28.1 CONTAINER HANDLING UNIT (CHU) SLIDER ARM ASSEMBLY REPAIR (CONT).

e. Installation.

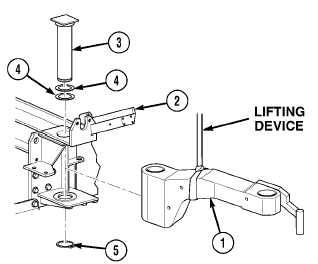

(1)

Apply grease to face of thrust washer,

seal, bore in arm assembly (1), and bores

and thrust face of rear roller bracket (2).

WARNING

Arm assembly weighs 240 lbs. (109 kg).

Attach suitable lifting device to prevent

possible injury to personnel.

(2)

Attach lifting device to arm

assembly (1).

CAUTION

Make sure not to damage bottom of

preformed packing during arm installation.

(3)

Soldier A and Soldier B position large

end of arm assembly (1) in rear roller

bracket (2).

WARNING

Use care when installing snap and retaining rings. Snap and retaining rings are under

spring tension and can act as projectiles when released and could cause severe eye injury.

NOTE

Install amount of shim(s) as noted prior to removal.

(4)

Apply grease to outer surface of pivot pin (3) and install pivot pin, shim(s) (4), and retaining

ring (5) in arm assembly (1) and rear roller bracket (2).

(5)

Remove lifting device from arm assembly (1).

f. Follow-on Maintenance.

(1)

Install horizontal roller (Para 4-48).

(2)

Install pin bracket assembly (Para 4-53.4).

(3)

Install slider/pivot assembly (Para 4-53.2).

(4)

Lubricate slider arm (Para 3-2).

(5)

Remove wheel chocks (TM 9-2320-279-10).

END OF TASK

5-29. OVERVIEW (HYDRAULIC SYSTEM).

The hydraulic pump is driven by the power takeoff (PTO) mounted on the transmission. There is a PTO switch

mounted in the cab to engage and disengage the PTO. The vehicle must be in neutral for proper operation of

the LHS.

Change 1

|