|

| |

TM 9-2320-304-14&P

5-80

Direct Support and General Support Maintenance (Cont)

5-15. GENERAL ASSEMBLY INSTRUCTIONS (CONT).

Table 5-3. Recommended Flats Rotation.

Dash

No.

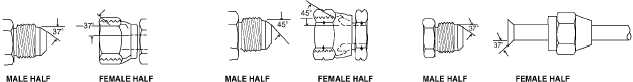

JIC 37 Degree

Flared Hose and Fitting

Machined Seat

SAE 45 Degree

Flared Hose and Fitting

Machined Seat

JIC 37 Degree

Flared Tube

-4

1 1/2 - 1 3/4

1 - 1 1/4

2 1/4 - 2 3/4

-5

1 - 1 1/2

1 - 1 1/4

2 1/4 - 2 3/4

-6

1 - 1 1/2

3/4 - 1

2 1/4 - 2 3/4

-8

1 1/4 - 1 3/4

1 - 1 1/4

2 1/4 - 2 3/4

-10

1 1/4 - 1 3/4

1 - 1 1/4

2 - 2 /2

-12

1 - 1 1/2

1 - 1 1/4

2 - 2 /2

-16

3/4 - 1

-----

2 1/4 - 2 3/4

-20

1/2 - 3/4

-----

1 1/4 - 2 3/4

-24

1/2 - 3/4

-----

3/4 - 1 1/4

-32

3/4

-----

1 - 1 1/4

g. Pipe Thread Tightening Procedures.

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors

and are harmful to skin and clothing. To avoid injury or death, keep away from open fire

and use in a well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or

clothing, wash immediately with soap and water.

CAUTION

Use sealing compound sparingly and only on male threads. Do not apply compound on first

two threads to avoid contamination of system from compound. Do not apply compound to

hose connections or fittings with preformed packings. Damage to equipment may result.

(1) Coat threads of male fitting with sealing compound, sealant, or adhesive as indicated in each

maintenance task.

(2) Position male fitting on female fitting finger-tight.

(3) Scribe alinement mark on both fittings.

CAUTION

·

It may be necessary to tighten fitting slightly more or less than 2 1/2 turns to match

position noted prior to removal. Do not loosen fitting to arrive at proper position or

a leak may occur.

·

Over-tightening may cause pipe fitting to deform and damage to the joining fitting,

flange or component.

(4) Tighten male fitting 2 1/2 (3 maximum) full turns past hand-tight position.

|