|

| |

TM 9-2320-304-14&P

5-79

Direct Support and General Support Maintenance (Cont)

5-15. GENERAL INSTALLATION INSTRUCTIONS.

a. Preparation. When unpacking items, remove all packing material, barrier paper, tape, plastic

bags, protective caps, and protective grease coatings. Handle and store removed components carefully.

CAUTION

Use sealing compound sparingly and only on male threads. Do not apply compound on first

two threads to avoid contamination of system from compound. Do not apply compound to

hose connections or fittings with preformed packings. Damage to equipment may result.

b. Sealing Compounds. Use sealing compounds as required in each maintenance task.

c. Torquing. Tighten bolts, screws, washers, hoses, and fittings as required in Appendix J or in each

maintenance task.

d. Identification Tags. Put hoses, tubes, lines, and electrical wiring in place by matching

identification tags and markings on equipment.

e. Hoses and Wiring. After installing hoses and wiring ensure that they do not contact moving part

or component edges. Secure in place, out of way with cable ties and cushion clips.

f. Hose and Fitting Tightening Procedure.

NOTE

Tighten hoses and fittings as required in

Appendix J or in each maintenance task.

If a torque wrench and crowsfoot are not

available or cannot be used, use the

following procedure.

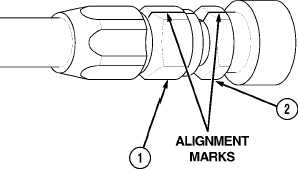

(1) Install hose nut (1) on fitting (2).

NOTE

When turning effort increases, hose nut

seat is in contact with adapter seat.

(2) Tighten hose nut (1) until seated on

fitting (2).

NOTE

Alinement marks allow the mechanic to

count the number of flats the hose nut has

rotated during tightening.

(3) Scribe alinement mark on hose nut (1)

and fitting (2).

(4) Tighten hose nut (1) until mark on hose

nut has rotated correct number of flats

(Refer to Table 5-3).

|