|

| |

TM 9-2320-304-14&P

4-234.76

Organizational Maintenance Instructions (Cont)

4-58. HYDRAULIC HOSE REPLACEMENT.

Special Tools

None

This task covers:

a. Typical Hydraulic Coupling Removal

d. Typical Clip, Clamp, and Bracket Installation

b. Typical Hydraulic Coupling Installation

e. Hydraulic Lines

c. Typical Clip, Clamp, and Bracket Removal

f. Follow-on Maintenance

INITIAL SETUP

Personnel Required

MOS 63S, Heavy wheel vehicle mechanic

Equipment Condition

TM or Para

Condition Description

TM 9-2320-279-10 Engine OFF

TM 9-2320-279-20 Hydraulic reservoir

drained (only when

replacing reservoir lines)

References

None

Models

M1120

Test Equipment

None

Special Environmental Conditions

None

General Safety Instructions

None

Supplies

Tags, Identification, Item 19, Appendix F

Ties, Cable, Item 4, Appendix F

NOTE

·

This procedure only shows location of LHS hydraulic lines. Refer to

TM 9-2320-279-20 for vehicle hydraulic lines. It will never be necessary to remove

all hydraulic lines at once.

·

All hydraulic lines are connected with compression fittings. Some fittings will not

have preformed packings. Fitting from which hydraulic line is being removed or

installed can be an elbow, tee, or adapter on a valve or other hydraulic component or

hydraulic lines. All compression fittings are removed and installed the same way.

Elbow fitting is shown.

·

Tag and mark position of all hydraulic lines. Cut plastic cable ties as necessary.

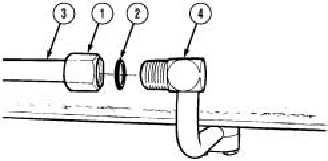

a. Typical Hydraulic Coupling Removal. Loosen

fitting (1). Remove preformed packing (2) and

hose (3) from elbow (4).

b. Typical Hydraulic Coupling

Installation. Install preformed packing (2) and

connect hose (3) on elbow (4) with fitting (1).

Change 1

|