|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

HOOD SHEET MOLDED COMPOUND (SMC) REPAIR - CONTINUED

0291 00

REPAIR - CONTINUED

NOTE

If joint between parts was separated for repair, rebond joint. Refer to Hood Component Rebonding on page

0291 00-7.

(3)

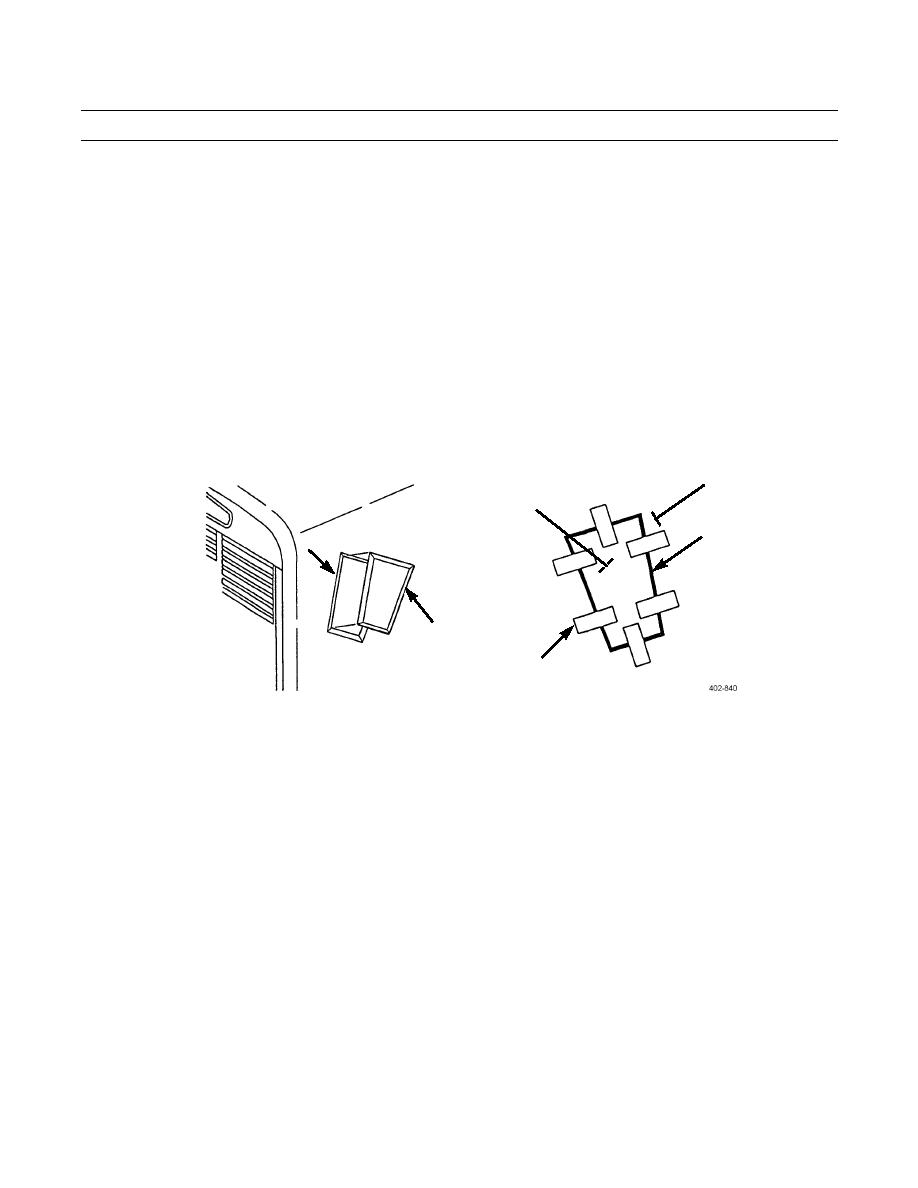

Hold patch (9) in place and bond strips (17) to hood (11) and patch where scuffed. Use Lord Fuser 320/322

to bond strips.

(4)

Apply light pressure and heat from heat gun to area for 3-5 minutes.

(5)

After Lord Fuser 320/322 has hardened, use 100-220 grit sandpaper to scuff strips.

(6)

Blow dust away with compressed air and wipe area with clean cloth.

11

9

10

8

9

17

m.

Using razor knife, cut sections of woven fiberglass cloth (18) to fully cover gap (10) between hood (11) and patch

(9), all around patch. Fiberglass cloth should overlay about 3/4 in (19 mm) on both sides of gap.

n.

Using wooden stir stick and measuring in spoonfuls, mix equal volumes of Magnolia 58 A and B epoxy resins on

clean sheet of glass, metal or section of scrap laminate. Mix 15 seconds.

o.

Use stir stick to spread thin layer of mixed epoxy resins over scuffed area on unexposed side of repair.

p.

Lay cut sections of fiberglass cloth (18) on repair area, centered over gap (10). Using stir stick, firmly press fiber-

glass cloth into epoxy to completely soak fiberglass cloth.

q.

Apply another layer of epoxy resins over fiberglass cloth (18).

r.

After 2-5 minutes, epoxy will start gelling. It may take more time in cool temperatures, less in hot temperatures.

NOTE

For smoother surface, press piece of masking tape, wider than repair, directly over wet epoxy and smooth

before epoxy hardens. Tape can be removed when epoxy sets up after 15 minutes.

s.

After body filler has hardened, sand unexposed side of repair area to smooth flat surface, if required.

0291 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |