|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

HOOD SHEET MOLDED COMPOUND (SMC) REPAIR - CONTINUED

0291 00

REPAIR - CONTINUED

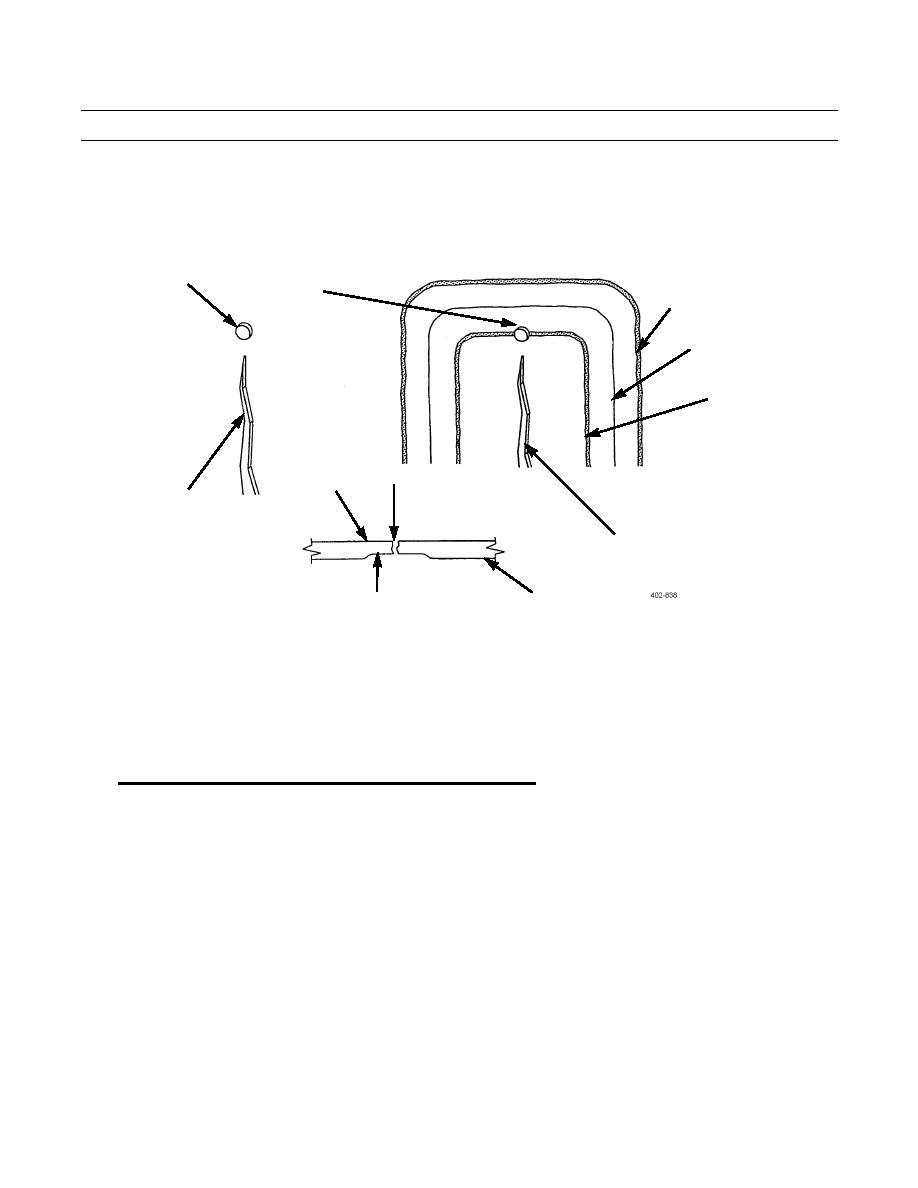

l.

Lay fiberglass cloth (4) on repair area, centered over damage. Using stir stick, firmly press fiberglass cloth into

epoxy to completely soak fiberglass cloth.

m.

Apply another layer of epoxy resins over fiberglass cloth (4).

1

1

3

4

5

2

7

2

2

6

5

n.

Allow 2-5 minutes for epoxy to start gelling. It may take more time in cool temperatures, less in hot temperatures.

NOTE

For smoother surface, press piece of masking tape, wider than repair, directly over wet epoxy and smooth

before epoxy hardens. Tape can be removed when epoxy sets up after 15 minutes.

o.

Patch should be hard enough in 15 minutes to allow sanding to smooth, flat surface, if required.

p.

Repair damage on outside surface of hood, and paint surface on both sides.

2.

Section Replacement (Repair of Punctures and Large Fractures). On large damaged areas (for example, structural

damage on side surface of the hood covering a square foot area), it may be easier to do a section replacement rather than

to make a patch. Fenders and headlight reinforcements are available for use in section replacements, or a second dam-

aged hood must be available as scrap with the needed section intact.

CAUTION

Piece of SMC laminate from another SMC laminate hood must be used for section replacement. Use of any

other material may not allow necessary bonding for repair.

a.

To determine extent of damage, push in on area immediately surrounding and underneath damaged area.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |