|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

BRAKE DRUM REPAIR

THIS WORK PACKAGE COVERS

Repair

INITIAL SETUP

Materials/Parts

Maintenance Level

Direct Support

Cloth, abrasive (Item 10, WP 0312 00)

Tools and Special Tools

Equipment Condition

Tool kit, general mechanic's (Item 102, WP 0313

Brakedrum removed from vehicle (WP 0154 00

Lathe, brakedrum (Item 53, WP 0313 00)

or WP 0155 00)

REPAIR

CAUTION

If maximum inside diameter is exceeded, to prevent damage to equipment, brake drum must be replaced.

1.

Check brake drum inside diameter. Refer to Table 1 for diameter.

2.

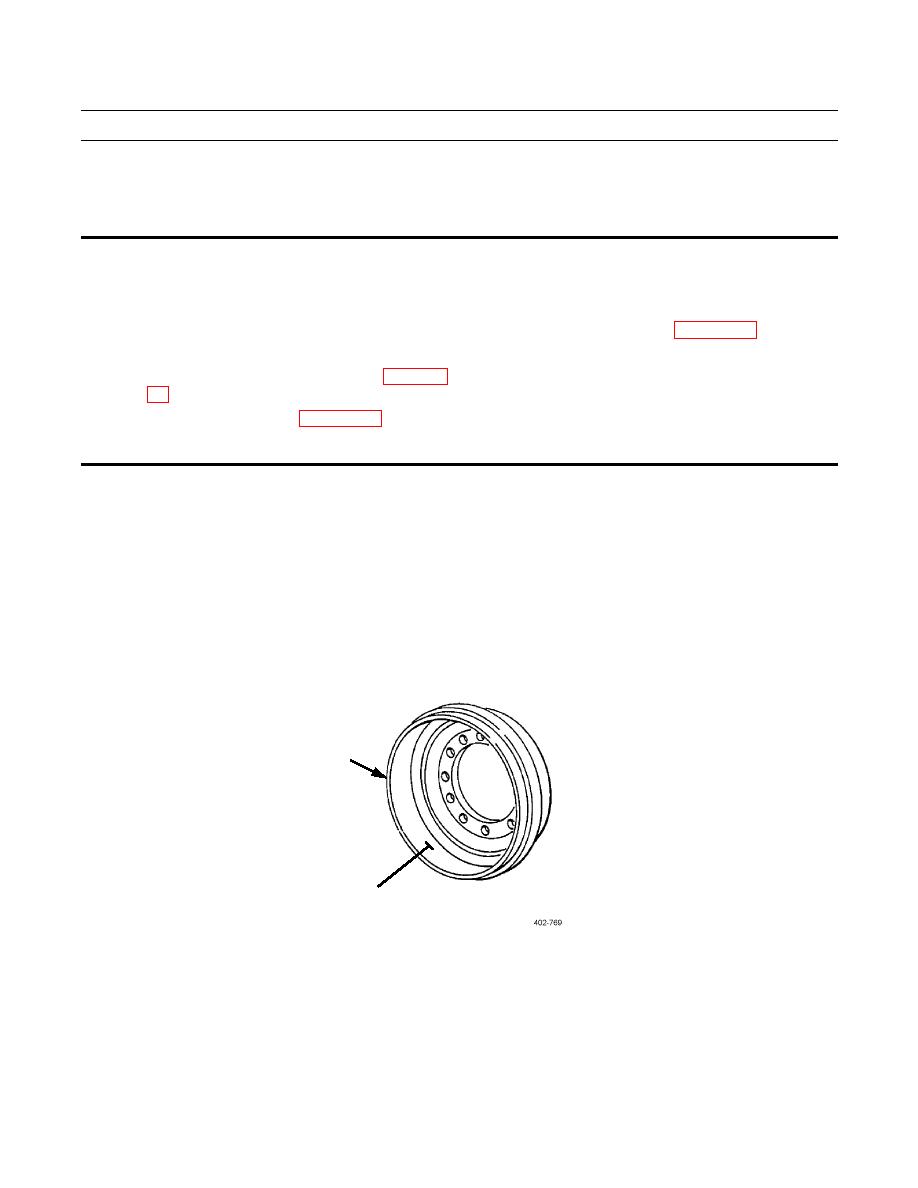

Brake drum (1) must be round within 0.003 in (0.076 mm). If brake drum is out-of-round, machine brake drum. Refer to

Table 1 for machining specifications.

1

2

3.

Check brake drum surface (2) for cracks or badly scored finish. If brake drum is cracked or scored, machine brake drum.

Refer to Table 1 for machining specifications.

4.

Check brake drum surface (2) for glossy or heat spots. If glossy or heat spots are visible, clean brake drum surface with

abrasive cloth.

5.

Check brake drum (1) for external or mating surface cracks. If cracks are visible, replace brake drum.

6.

Check brake drum (1) for balance weight. If balance weight is missing, replace brake drum.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |