|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

FORWARD-REAR AXLE DIFFERENTIAL CARRIER REPAIR - CONTINUED

0257 00

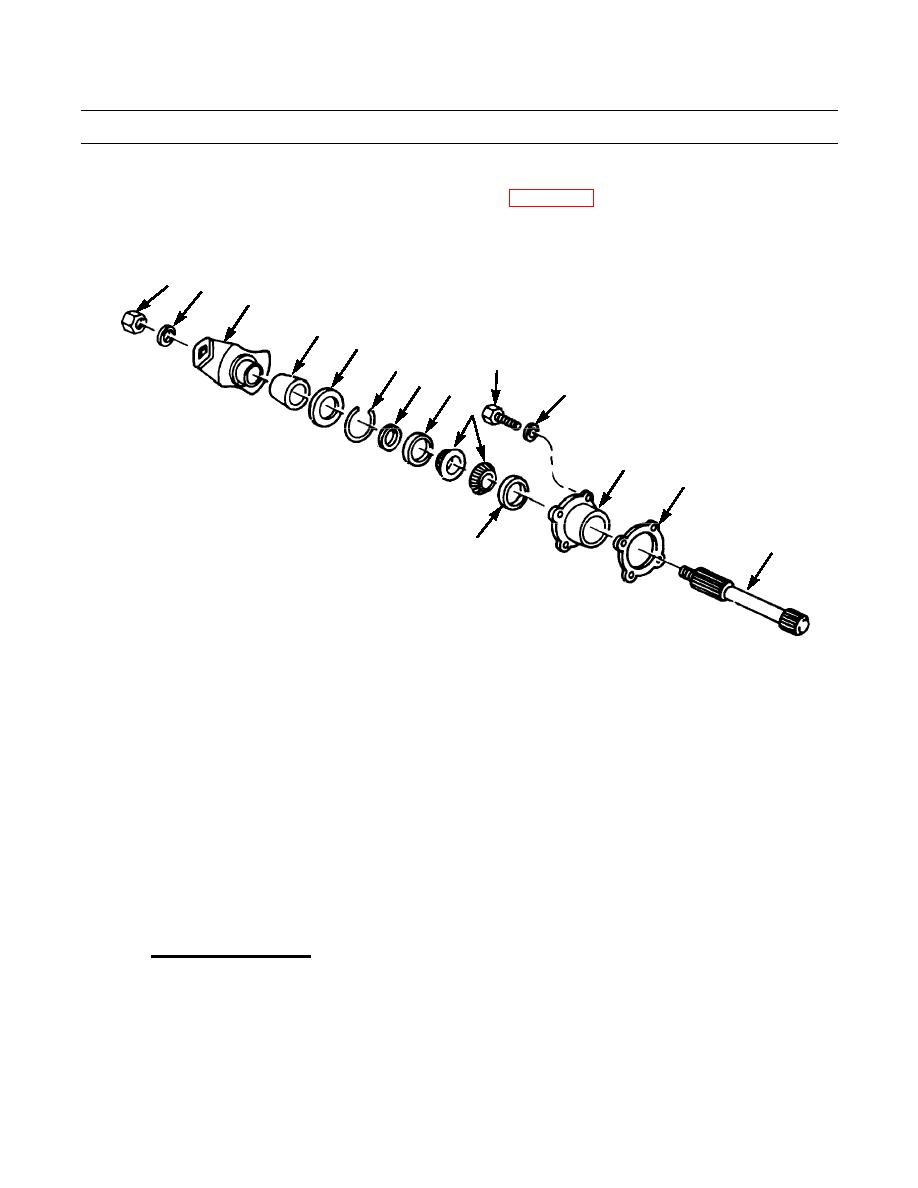

OUTPUT SHAFT ASSEMBLY

a.

Coat bearings (11) with recommended axle lubricant (Item 33, WP 0312 00) and press both inner and outer bearing

cones (back-to-back) onto end of output shaft (14) until inner bearing cone bottoms on the shaft shoulder. Use a

press and suitable sleeve.

1

2

3

4

5

8

6

7

10

9

11

12

13

14

10

402-697

CAUTION

Use soft metal shields over vise jaws to avoid damaging the cage.

b.

Secure the output shaft cage (12) in a vise and place the inner bearing cup (10) in position in the cage and insert the

output shaft with bearing cones (11) through the cage.

c.

Position the outer bearing cup (10) into the cage (12) and over the bearing cone (11) on the output shaft (14).

Secure bearings and shaft in the cage with a washer (7) and retaining ring (6), snap ring bearing spacer (5). This

retaining ring also controls the bearing end play.

NOTE

Do not assemble the oil seal or yoke at this time.

OUTPUT SHAFT INSTALLATION

Adjust Bearing End Play.

a.

NOTE

The output bearing end play is controlled by the thickness of the retaining ring (6). The retaining ring is

available in thicknesses ranging from 0.155-0.182 inch in increments of 0.003 inch. Select and install one

retaining ring to obtain a 0.0001-0.0030 inch (0.0025-0.0762 mm) bearing end play. Use the following pro-

cedures.

0257 00-50

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |