|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

FORWARD-REAR AXLE DIFFERENTIAL CARRIER REPAIR - CONTINUED

0257 00

DIFFERENTIAL CARRIER ASSEMBLY - CONTINUED

NOTE

Add shims to increase end play; remove shims to decrease end play.

(9)

After correct end play has been established, torque the input yoke nut (16) to 450-600 lb-ft (610-813 Nm).

p.

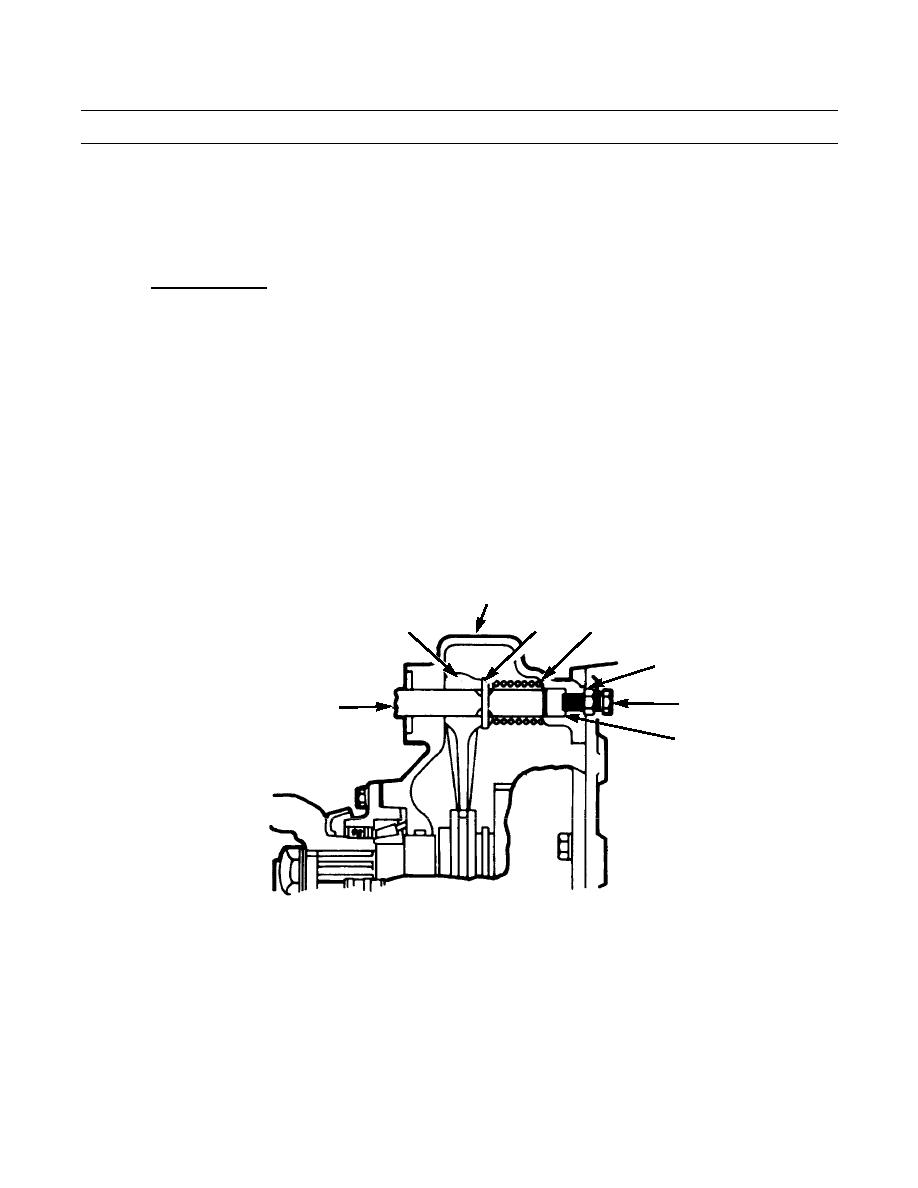

Adjust Shift Shaft.

(1)

If the shift shaft adjusting screw (78) and jam nut (79) have not been assembled, install both parts into the

gear cover (17) in back of the shift shaft (91). Turn in the adjusting screw approximately two turns at this

time.

(2)

Using a shop air supply, apply air pressure to the air chamber. This will move the shift shaft (46), fork (47)

and collar (48) back, locking the interaxle differential.

(3)

Make sure the collar (48) travels over the splines (49) and engages with the rear side gear (55). If neces-

sary, index the shift collar by turning the input shaft.

(4)

With the shift shaft (46) moved back its full travel, turn in the adjusting screw (78) until it just touches the

end of the shift shaft.

(5)

From this point continue turning in screw (78) 1-1 1/4 turns more and lock adjusting screw with jam nut

(79); torque jam nut to 40-55 lb-ft (54-75 Nm). This will allow correct clearance between the fork (47) and

groove of the collar, thus eliminating wear.

(6)

After shift shaft (46) adjustment has been made, remove the air line from the air chamber.

17

49

47

48

79

78

46

55

402-688

0257 00-49

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |