|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

FORWARD-REAR AXLE DIFFERENTIAL CARRIER REPAIR - CONTINUED

0257 00

DIFFERENTIAL CARRIER ASSEMBLY - CONTINUED

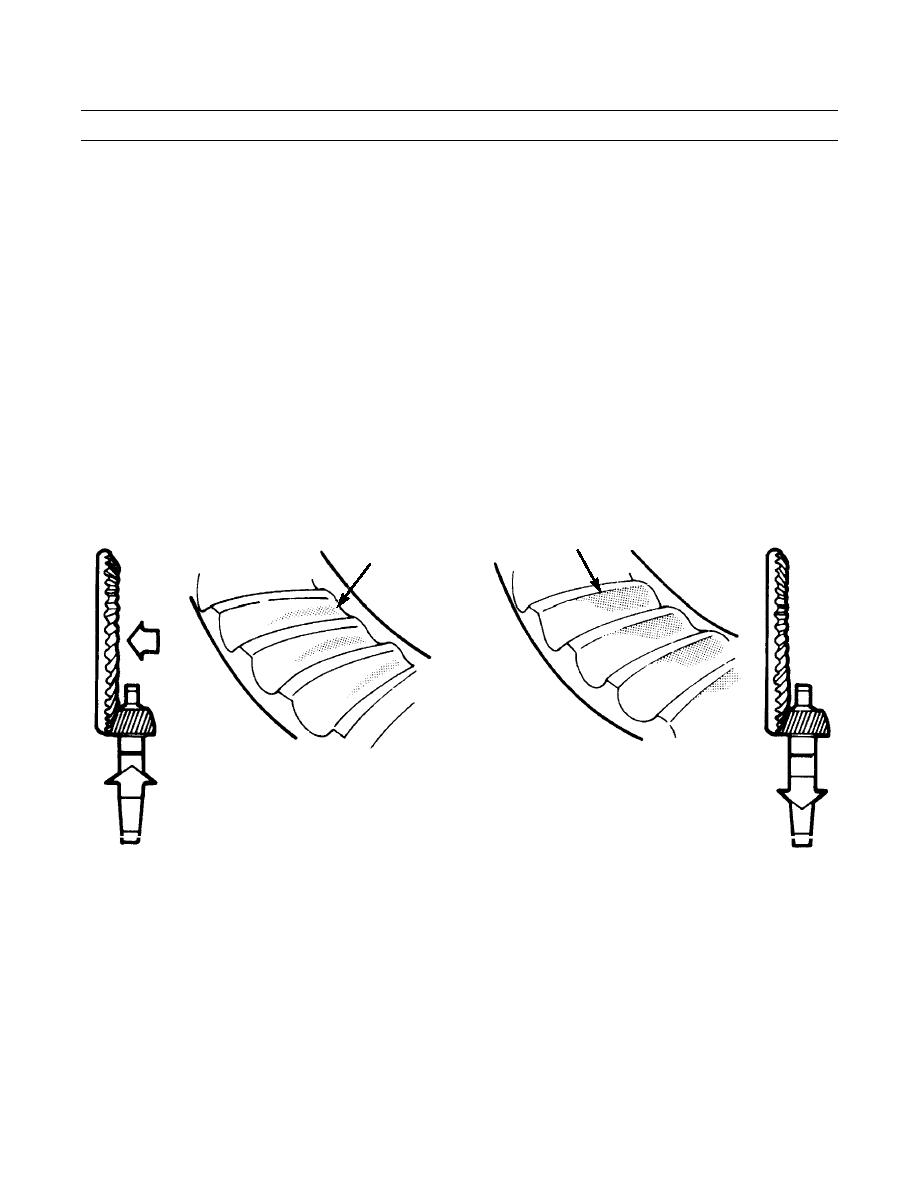

(6)

With adjustments properly made (pinion at correct depth and backlash set at 0.010 in. (0.254 mm) the con-

tacts will be procured. The area of contact favors the toe and is centered between the top and bottom of the

tooth.

(7)

After final adjustments, install cotter pins in adjusting rings.

(8)

The hand-rolled pattern shown (gears unloaded), will result in a pattern centered in the length of the tooth

when the gears are under load, as shown (gears loaded). The loaded pattern will be almost full length and

the top of pattern will approach the top of the gear tooth.

(9)

The pattern on the coast side of teeth will appear the same width as the drive side shown above; however,

the overall length will be centered between the toe and heel of gear tooth, After the correct contacts, as

shown, have been established with a backlash of 0.010 in. (0.254 mm), open the backlash to measure

between 0.005-0.015 in. (0.127-0.381 mm), if required.

(10)

Set used gear to have the tooth contacts to match wear patterns. Hand-rolled patterns of used gears will be

smaller in area and should be at the toe end of wear patterns.

(11)

Incorrect patterns are shown. A low contact indicates pinion is too deep. Set the pinion to the correct depth

by adding shims under the bearing cage. Slight inward movement of the gear may be necessary to maintain

correct backlash.

LOW PATTERN

HIGH PATTERN

402-680

0257 00-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |