|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

FORWARD-REAR AXLE DIFFERENTIAL CARRIER REPAIR - CONTINUED

0257 00

DIFFERENTIAL CARRIER ASSEMBLY - CONTINUED

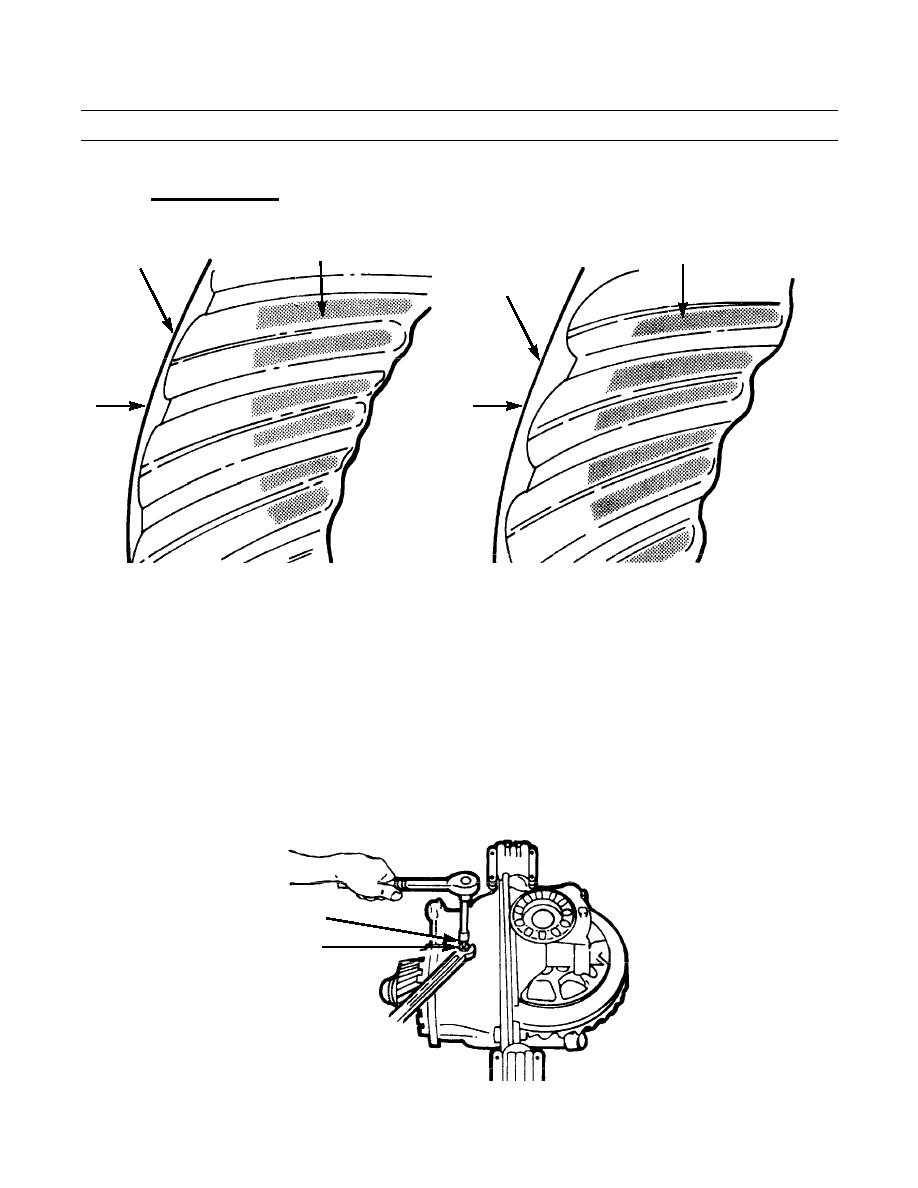

Check Tool Contact.

f.

TOOTH CONTACT

TOOTH CONTACT

(GEARS LOADED)

(GEARS UNLOADED)

77

77

TOE

TOE

402-679

(1)

Apply a coat of Prussian blue paste lightly to the ring gear (77) teeth. When the pinion is rotated, the blue

paste is squeezed away by the contact of the teeth, leaving bare areas the exact size, shape, and location of

the contacts.

(2)

Sharper hand roll impressions may be obtained by applying a small amount of resistance to the gear with a

flat steel bar and using a wrench to rotate the pinion. When making adjustments, check the drive side of the

gear teeth. Coast side should be automatically correct when drive side is correct. As a rule, coating about

twelve teeth is sufficient for checking purposes.

(3)

After obtaining a satisfactory tooth contact, the backlash can be altered within the limits of 0.005-0.015 in.

(0.127-0.381 mm) for forward rear axle. Use 0.008-0.020 in. (0.203-0.508 mm) for rear-rear axle gears to

obtain a better contact position relative to the length of the tooth.

(4)

A high backlash setting can be used to keep the contact from starting too close to the toe, and a low back-

lash setting can be used to keep the contact from starting too far away from the toe.

(5)

After correct tooth contact has been established, install thrust screw (78) and jam nut (79).

78

79

402-681

0257 00-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |