|

|||

|

|

|||

|

Page Title:

Rotating Clutch Module Disassembly |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

TRANSMISSION OVERHAUL - CONTINUED

0248 00

MODULE OVERHAUL - CONTINUED

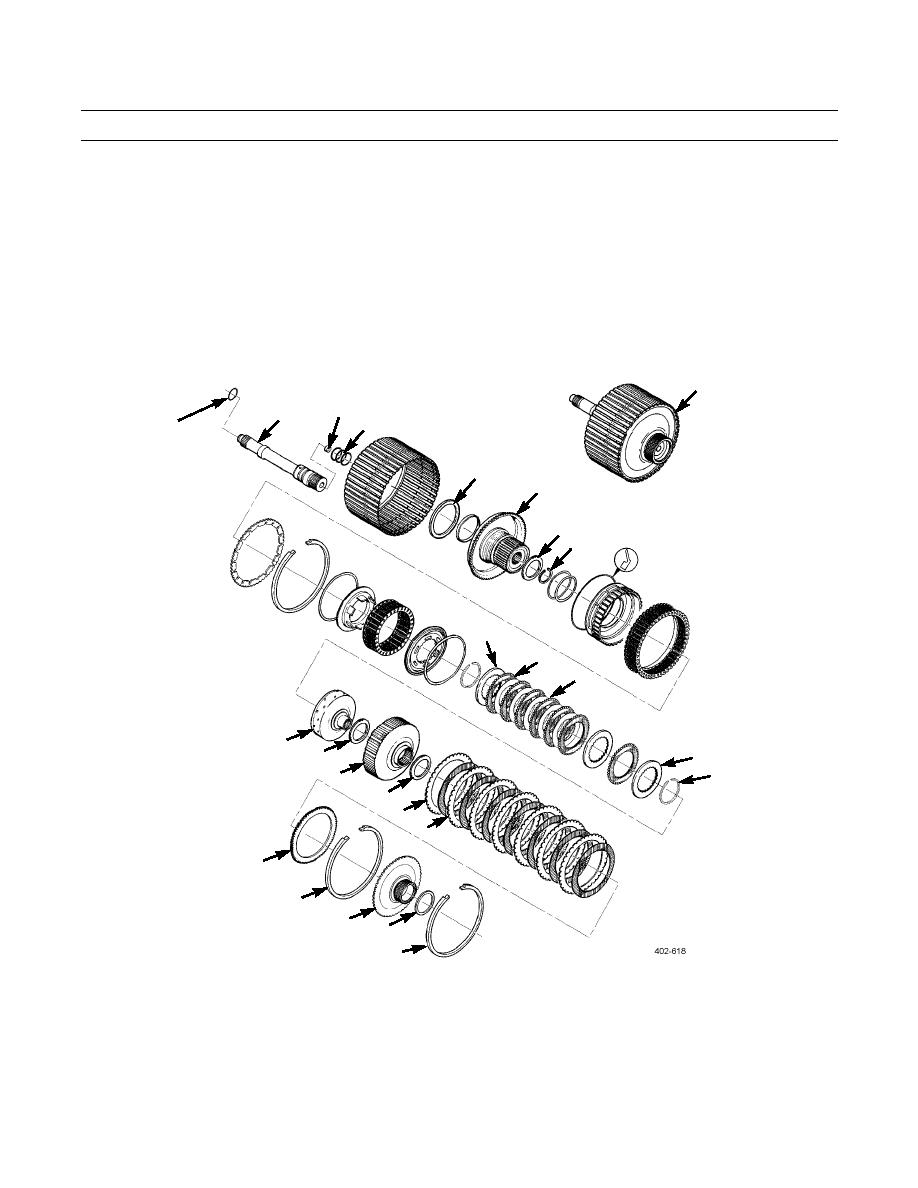

Rotating Clutch Module Disassembly

1.

Remove thrust bearing (5) and retaining ring (19) from rotating clutch module (9). Inspect thrust bearing. If worn, dis-

card.

2.

Remove P1 sun gear assembly (21) and thrust bearing (20) from rotating clutch module (9).

3.

Remove C2 retaining ring (22) and backplate (23).

4.

Measure wear surface thickness of C2 backplate (23). Minimum thickness allowed is 0.311 in (7.90 mm). Check flat-

ness of backplate. Maximum allowable distortion is 0.006 in (0.15 mm).

9

3

2

4

1

5

6

7

8

10

11

12

18

16

10

13

17

16

15

14

23

22

21

20

19

5.

Remove C2 clutch pack containing seven friction plates (14) and seven steel reaction plates (15). Perform the following

measurements:

a.

Friction plate thickness: minimum thickness allowed is 0.115 in (2.92 mm).

b.

Friction plate oil groove depth: minimum depth allowed is 0.008 in (0.20 mm).

c.

Friction plate cone: maximum cone allowed is 0.010 in (0.25 mm).

0248 00-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |