|

|||

|

|

|||

|

Page Title:

Torque Converter Module Assembly - Continued |

|

||

| ||||||||||

|

|

TM 9-2320-303-24-2

TRANSMISSION OVERHAUL - CONTINUED

0248 00

MODULE OVERHAUL - CONTINUED

Torque Converter Module Assembly - Continued

NOTE

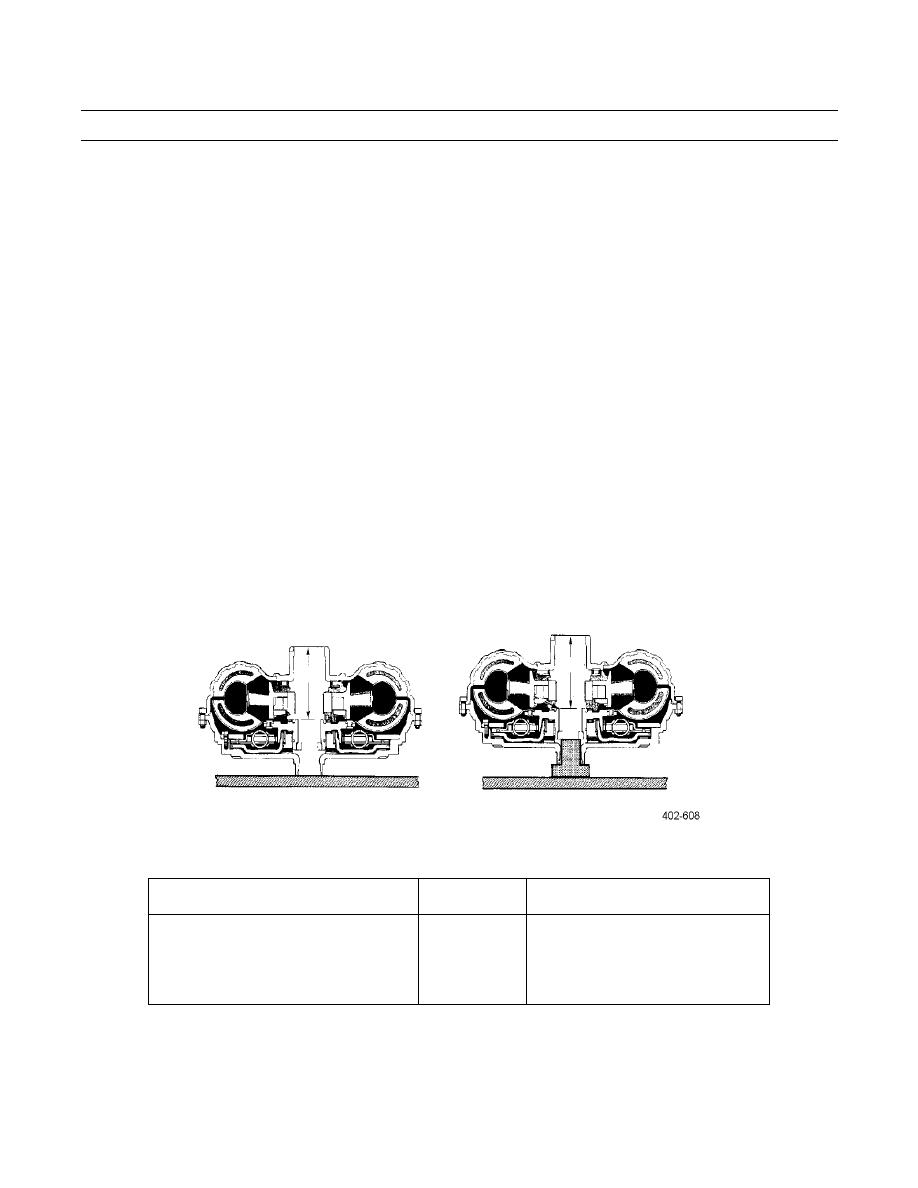

Perform steps 22 through 27 to determine torque converter selective shim dimensions.

22.

Using a depth micrometer, measure from top of torque converter drive tang surface to thrust surface of turbine hub. This

dimension is "A".

23.

Remove bolt from tool (J38548). Install tool into torque converter and position converter on work surface so converter is

supported by tool.

24.

Using a depth micrometer, measure from top of torque converter drive tang surface to thrust surface of turbine hub. This

dimension is "B".

25.

Subtract dimension "B" from dimension "A" to get dimension "C".

26.

Dimension "C" should be 0.0060-0.0139 in (0.153-0.353 mm). If dimension is not correct, a shim is required. If the

dimension is correct, proceed to step 29.

27.

If a shim is required, select appropriate shim from list below:

SHIM LOCATION

DRIVE TANG

DRIVE TANG

THRUST

SURFACE

SURFACE

SURFACE

THRUST

OF

SURFACE

TURBINE

OF TURBINE

HUB

HUB

J 38548

Dimension C

Use P/N

Shim Thickness

0.0140-0.0229 inch (0.356-0.581 mm)

29503879

0.009-0.011 inch (0.23-0.27 mm)

0.0230-0.0319 inch (0.585-0.810 mm)

29503880

0.018-0.020 inch (0.46-0.50 mm)

0.0320-0.0394 inch (0.813-1.000 mm)

29503881

0.027-0.029 inch (0.69-0.73 mm)

28.

Disassemble torque converter and install selected shim. Repeat step 22 through 27 to confirm dimension "C".

29.

Install remaining 32 nuts (1) and tighten to 22-26 lb-ft (30-35 Nm).

0248 00-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |