|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-303-24-2

ENGINE TROUBLESHOOTING

THIS WORK PACKAGE COVERS

Engine Troubleshooting Procedures

INITIAL SETUP

Materials/Parts

Maintenance Level

Rag, wiping (Item 39, WP 0312 00)

Direct Support

Tools and Special Tools

Tool kit, general mechanic's (Item 102, WP 0313 00)

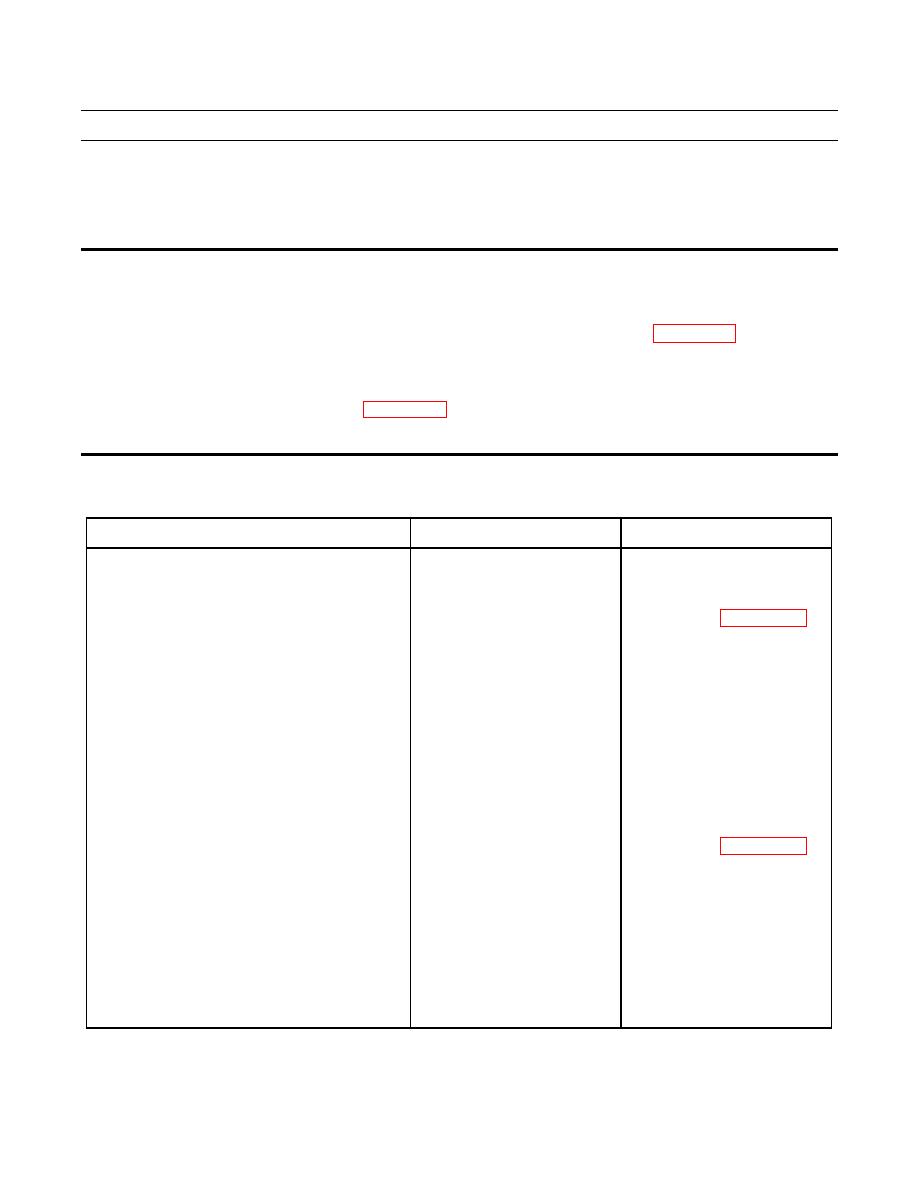

Table 1. Engine Troubleshooting Procedures.

MALFUNCTION

TEST or INSPECTION

CORRECTIVE ACTION

1. Engine Troubleshooting.

Refer to WP 0006 00.

2. Engine Fails to Crank.

Using accessory drive, attempt to If engine cannot be rotated,

rotate engine.

internal damage is indicated.

Remove engine (WP 0229 00).

3. Engine Cranks, But Does Not Start.

1. Inspect engine gear train for Refer to TM 9-2815-225-34&P.

correct timing mark alignment.

2. Inspect engine gear train for Refer to TM 9-2815-225-34&P.

damaged or missing gear teeth.

4. Engine Runs Erratically.

1. Inspect engine gear train for Refer to TM 9-2815-225-34&P.

correct timing mark alignment.

2. Inspect engine gear train for Refer to TM 9-2815-225-34&P.

damaged or missing gear teeth.

5. High Oil Consumption.

1. Clean and inspect engine for If no oil leaks are identified,

signs of external oil leaks.

internal damage is indicated.

Remove engine (WP 0229 00).

2. Inspect rear of engine for signs Refer to TM 9-2815-225-34&P.

of leaking oil.

3. Inspect front of engine for signs Refer to TM 9-2815-225-34&P.

of leaking oil.

4. Inspect turbocharger for signs Refer to TM 9-2815-225-34&P.

of leaking oil.

5. Inspect oil pan for signs of Refer to TM 9-2815-225-34&P.

leaking oil.

END OF WORK PACKAGE

0224 00-1/2 blank

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |