|

|||

|

|

|||

|

Page Title:

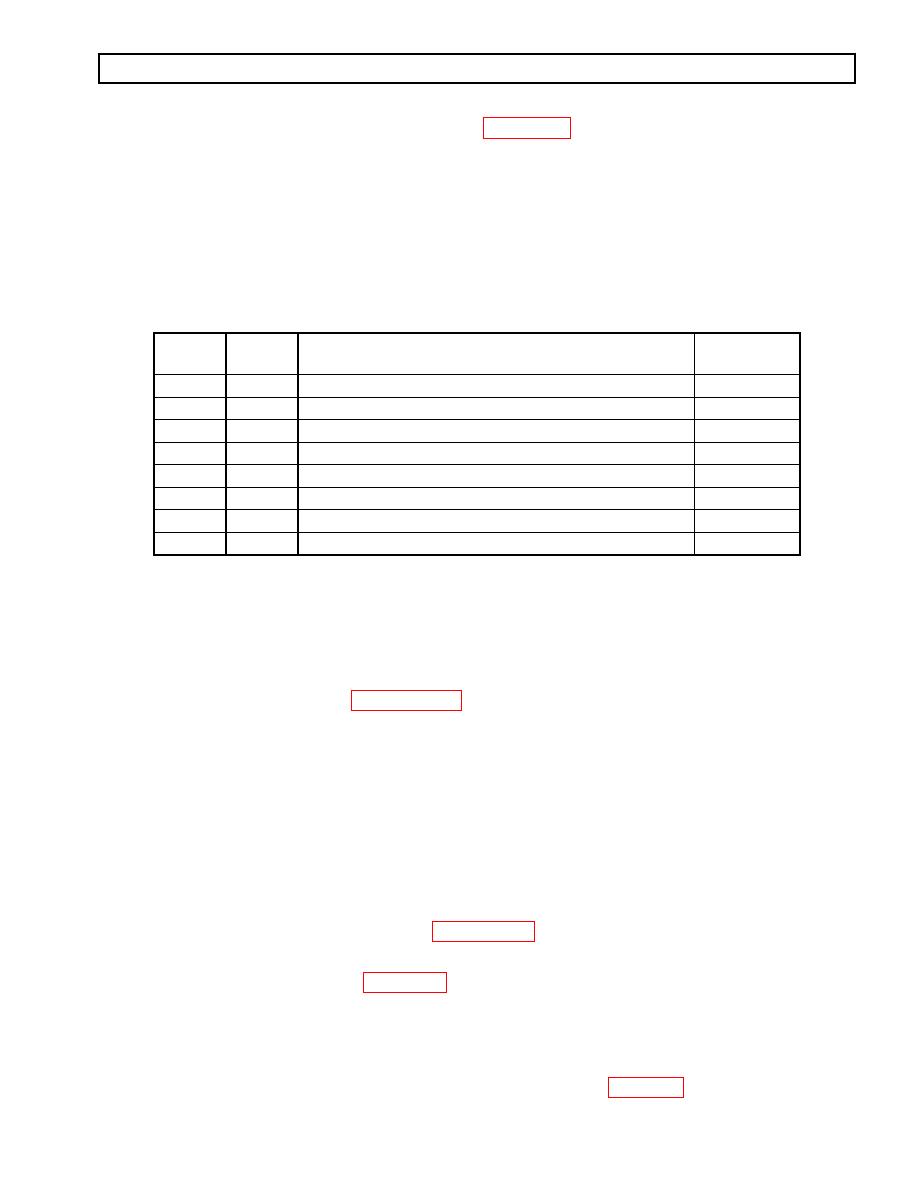

Figure 59. Code 25 Schematic Drawing |

|

||

| ||||||||||

|

|

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

CODE 25 XX -- OUTPUT SPEED SENSOR, DETECTED AT ZERO SPEED,

Main code 25 occurs if the output speed sensor reports a zero speed reading while both engine and turbine speeds

are approximately equal, turbine speed is above a calibration value, and neutral is not selected or commanded.

Main code 25 indicates either the output speed sensor has failed or the required oncoming clutch or clutches did not

come on. Code 25 11 can be generated by a false turbine speed reading. This may be due to crosstalk between

solenoid and turbine speed sensor circuits caused by direct wire-to-wire short or by water in the electrical

connectors. See Section 4 for corrective action.

NOTE:

If code 25 XX is in memory at ECU initialization (ignition on), all display segments are illuminated.

Main

Applied

Code

Subcode

Meaning

Clutches

25

00

Output speed sensor, detected at zero speed, Low range

C3, C6

25

11

Output speed sensor, detected at zero speed, 1st range

C1, C5

25

22

Output speed sensor, detected at zero speed, 2nd range

C1, C4

25

33

Output speed sensor, detected at zero speed, 3rd range

C1, C3

25

44

Output speed sensor, detected at zero speed, 4th range

C1, C2

25

55

Output speed sensor, detected at zero speed, 5th range

C2, C3

25

66

Output speed sensor, detected at zero speed, 6th range

C2, C4

25

77

Output speed sensor, detected at zero speed, Reverse

C3, C5

A.

Active Indicator Clearing Procedure:

Power down

Manual

Self-clearing

NOTE:

Before troubleshooting, read Paragraph 56. Also, check battery and ECU input voltages.

NOTE:

Intermittent connections or lack of battery-direct power and ground connections can cause this and

other codes.

B.

Troubleshooting:

1. Check the transmission fluid level and ensure correct fluid level.

2. Check for the presence of code 22 16. If code 22 16 is in the code list, go to code 22 XX section

and follow troubleshooting steps for code 22 16.

3. Connect the Pro-Link 9000 with ignition on, engine off; check for indication of turbine speed. If

turbine speed is indicated, refer to Paragraph 42 for corrective action.

4. If the output speed sensor and wiring are satisfactory, install pressure gauges into the appropriate

clutch pressure taps (see Appendix B in this manual) and make the shift again. See if either of the

clutches has low or no pressure. Lack of pressure in C1 in first range may be due to a G solenoid

stuck closed. Lack of pressure in C5 in first range may be due to an E solenoid stuck closed.

5. If a clutch is leaking pressure, drain the fluid, remove the control module and check for damaged

valve body gaskets and stuck or sticky valves. If no problems are found, replace the solenoids for

the clutches used in the range indicated by the code (refer to Figure 51). Refer to the appropriate

transmission Service Manual for replacement procedure.

0021 0071

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |