|

|||

|

|

|||

|

Page Title:

CODE 22 XX -- SPEED SENSOR/CIRCUITRY FAULT (Figure 55) |

|

||

| ||||||||||

|

|

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

DIAGNOSTIC CODE T

Main code 22 indicates a fault within a speed sensor, the wiring to a speed sensor, incorrect speed sensor gap, or

damaged bumps or teeth which create the speed signal. This fault is determined by the reasonableness of a speed

sensor signal when compared with the other two speed sensors and the commanded range. A speed sensor will not

pass the reasonableness test if there is no signal at all from that sensor when a signal should be present.

NOTE:

If turbine speed is below 150 rpm when output speed is below 100 rpm and engine speed is above

400 rpm, Neutral Very Low (NVL) is commanded when N (Neutral) is the range selected. NVL is

attained by turning D solenoid "ON" in addition to E solenoid. This causes the output to be locked

(C4 and C5 clutch applied).

NOTE:

If the engine speed sensor code (22 14) is active and a range verification test is failed, the range

verification code will not be set but a DO NOT SHIFT response is commanded.

Main Code

Subcode

Failed Sensor

22

14

Engine Speed

22

15

Turbine Speed

22

16

Output Speed

A.

Active Indicator Clearing Procedure:

Power down

Manual

Self-clearing

NOTE:

Before troubleshooting, read Paragraph 56. Also, check the ECU input voltage.

B.

Troubleshooting:

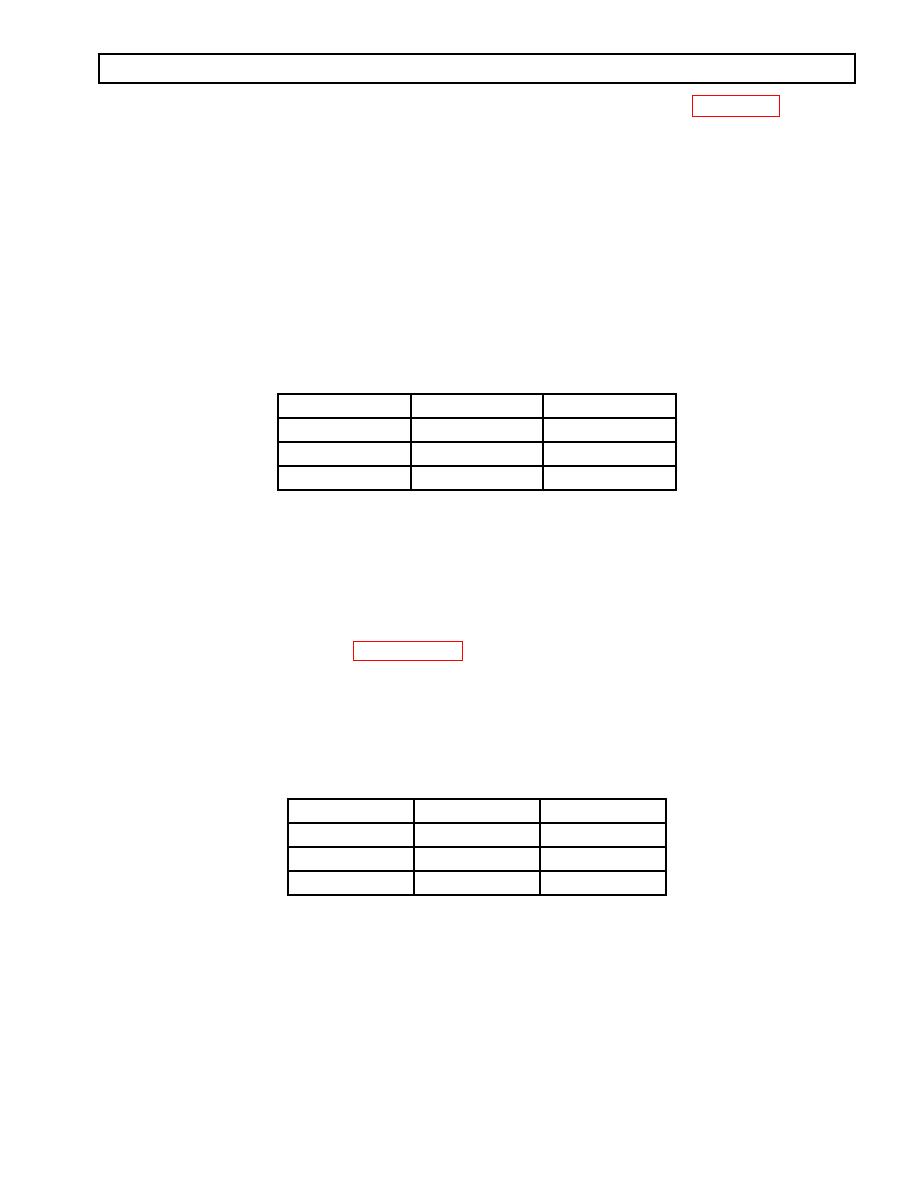

1. Check to see if the sensor is loose, missing, or disconnected. If not, disconnect the wiring harness

from the sensor and measure the resistance of the sensor (see chart below). Also check the termi-

nals for dirt, corrosion, or damage. If resistance is not correct, replace the sensor.

Resistance

Temp C

Temp F

200

40

40

300

20

68

400

110

230

2. Remove the transmission harness connector from the ECU. Check the sensor circuit (in the exter-

nal harness) for open wires, shorts between wires, or shorts-to-ground. Isolate and repair any

faults.

3. If no opens or shorts are found, the condition must be intermittent. Replace the sensor indicated

by the trouble code. Before replacing a speed sensor, check the sensor for physical damage or

contamination. Refer to the appropriate transmission Service Manual for proper replacement pro-

cedure.

4. If the condition recurs, install new wiring (twisted-pair) for the sensor circuit between the ECU

and the transmission. Use St. Clair P/N 200153 Service Harness Twisted Pair for this purpose.

0021 0059

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |