|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-302-20-2

HOOD ADJUSTMENT

THIS WORK PACKAGE COVERS

Adjustment Check, Adjustment

INITIAL SETUP

Tools and Special Tools

Materials/Parts - Continued

Nut, lock (P/N M45913/1-5CG5C) (8)

Tool kit, general mechanic's (Item 50, WP 0306 00)

Shim(s) (P/N 17-10320-001)

Bar, wrecking (Item 3, WP 0306 00)

Wrench, torque, 0-300 lb-in (Item 56, WP 0306 00)

Personnel Required

Wrench, torque, 50-250 lb-ft (Item 58, WP 0306 00)

Two

Materials/Parts

References

Nut, lock (P/N 23-09336-005) (2)

TM 9-2320-302-10

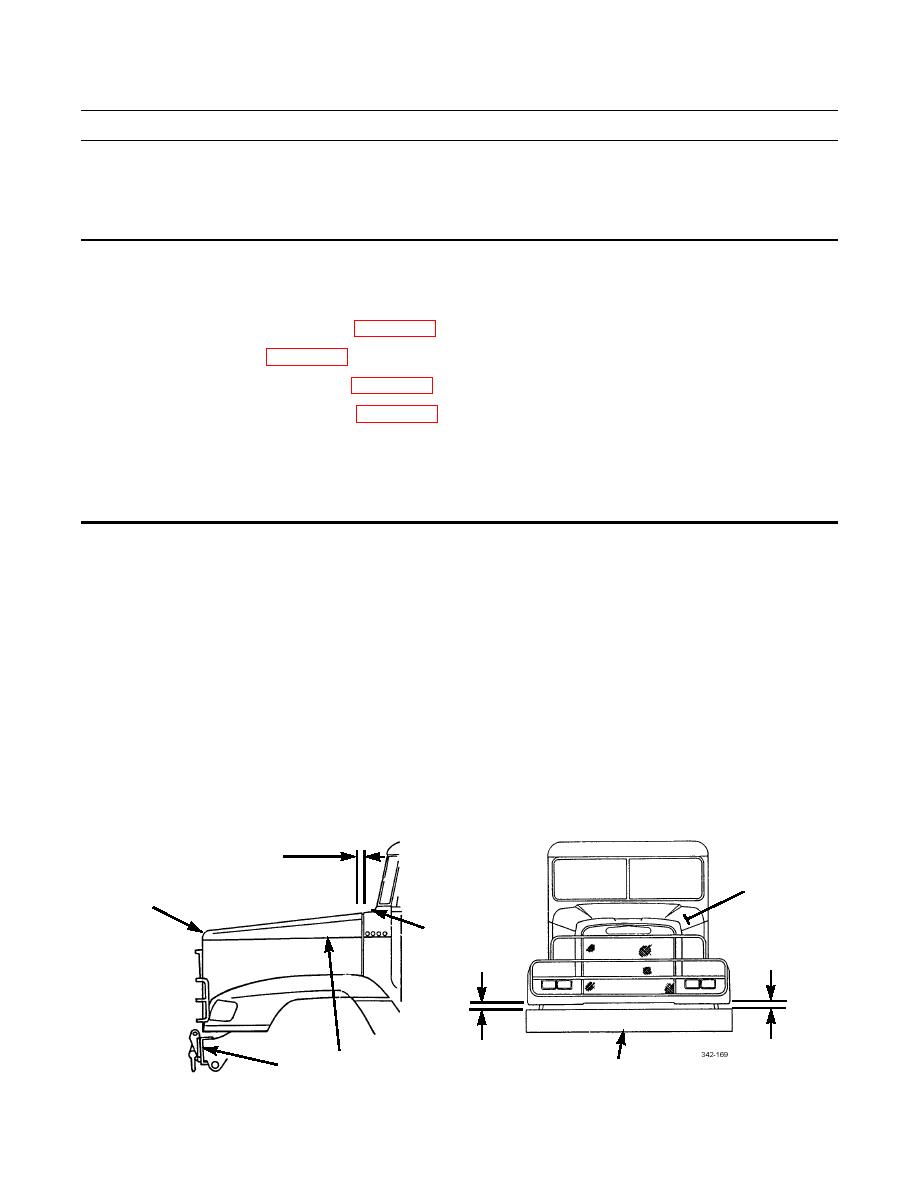

ADJUSTMENT CHECK

NOTE

Perform steps 1 through 3 to determine if hood adjustment is necessary.

1.

Measure and note gap between rear edge of hood (1) and cowl (2) at seam and at 8 in (203 mm) below seam. Gap should

be 1/2-3/4 in (13-19 mm).

2.

Check that front of hood (1) is centered with bumper (3). Check that space between top edge of bumper (3) and lower

edge of hood (1) is equal at both ends.

3.

Ensure that hood (1) is not touching any components attached to frame. If any components are touching hood, identify

and correct problem, and repeat steps 1 and 2.

1/2-3/4 in (13-19 mm)

Clearance

1

1

2

Both Sides

Seam

Equal

3

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |