|

|||

|

|

|||

|

Page Title:

Figure 18. Removal Tool Insertion. |

|

||

| ||||||||||

|

|

TM 9-2320-302-20-2

ELECTRICAL CONNECTORS MAINTENANCE - CONTINUED

0151 00

COMMERCIAL CONNECTOR REPAIR - CONTINUED

(2)

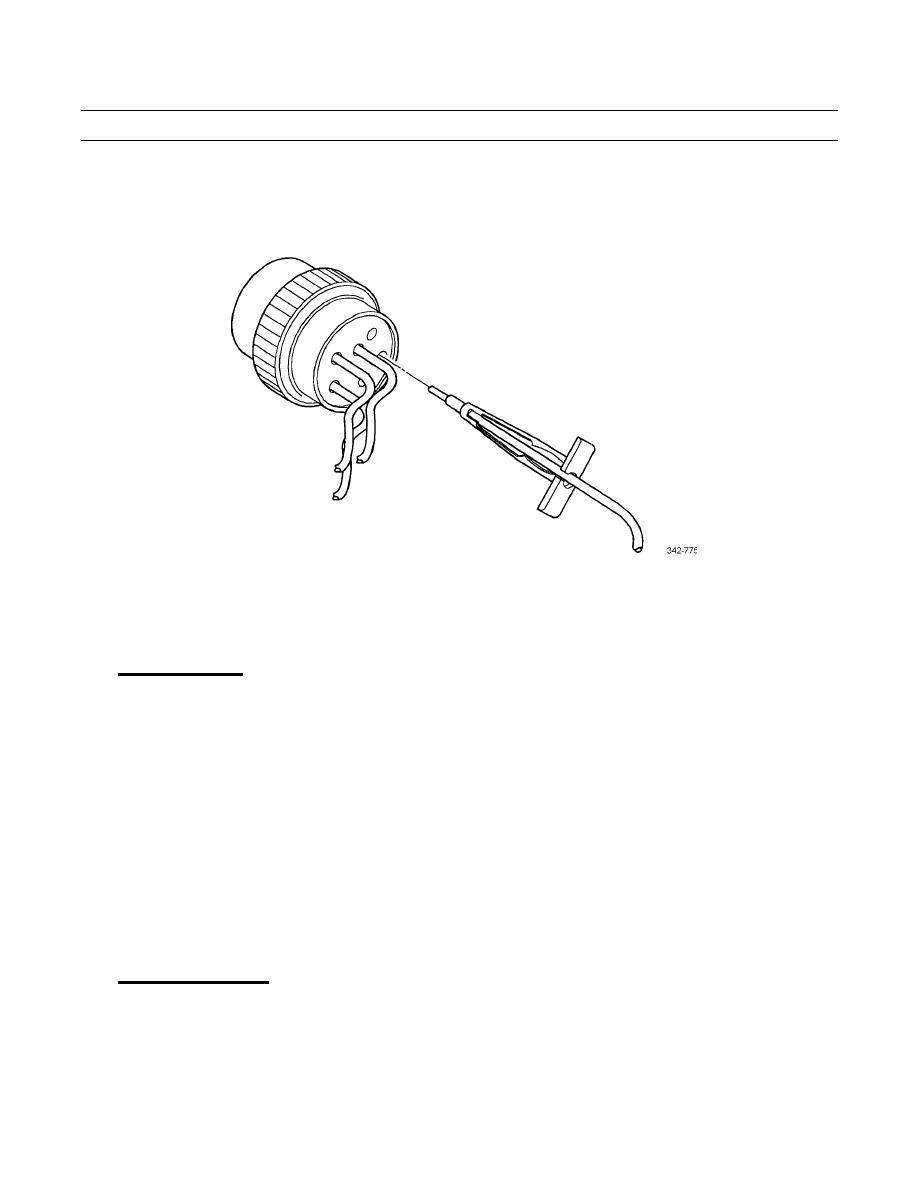

Slide tool along cable into insert cavity until it engages and resistance is felt. DO NOT twist or insert tool

at an angle (Figure 18).

Figure 18. Removal Tool Insertion.

(3)

Pull contact cable assembly out of connector. Keep reverse tension on cable and forward tension on tool.

SPLICING

Splicing Guidelines.

1.

a.

The following are guidelines which may be used for splices. The methods described are not the only acceptable

methods. Any method should produce a high quality, tight splice with durable insulation which can be expected to

last the life of the vehicle.

b.

The selection of crimpers and splice connectors is optional. Select a high quality crimper equivalent to Kent-

Moore tool J38706 and commercially available splice clips.

c.

The following is a list of tools required for splicing wires:

Soldering iron

Rosin core solder

Wire strippers

Heat shrink tubing

Splice clips

Crimp pliers

Splicing Straight Leads.

2.

a.

Locate broken wire.

b.

Remove insulation as required. Ensure exposed wire is clean and not corroded.

c.

Slide a sleeve of shrink wrap on wire long enough to cover splice and overlap wire insulation, about 1/4 in (6.4

mm) on both sides.

0151 00-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |