|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-273-10

Table 3-1. Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

22. FLUID LEAKING FROM TRANSMISSION BREATHER.

Check for evidence of foamy fluid on transmission dipstick.

Refer to Malfunction 19.

WHEELS, TIRES AND HUBS

23. WHEEL WOBBLES.

Step 1. Check wheel for loose or missing lug nuts.

Tighten loose nuts; notify Organizational Maintenance to

torque nuts properly. If any lug is broken or missing,

notify Organizational Maintenance.

Step 2. Check to see if wheel is bent.

If wheel is bent, change wheel and tire assembly. Notify

Organizational Maintenance that a replacement is needed.

Step 3. Check for loose, worn or damaged components.

Notify Organizational Maintenance of any suspension

problems.

24.

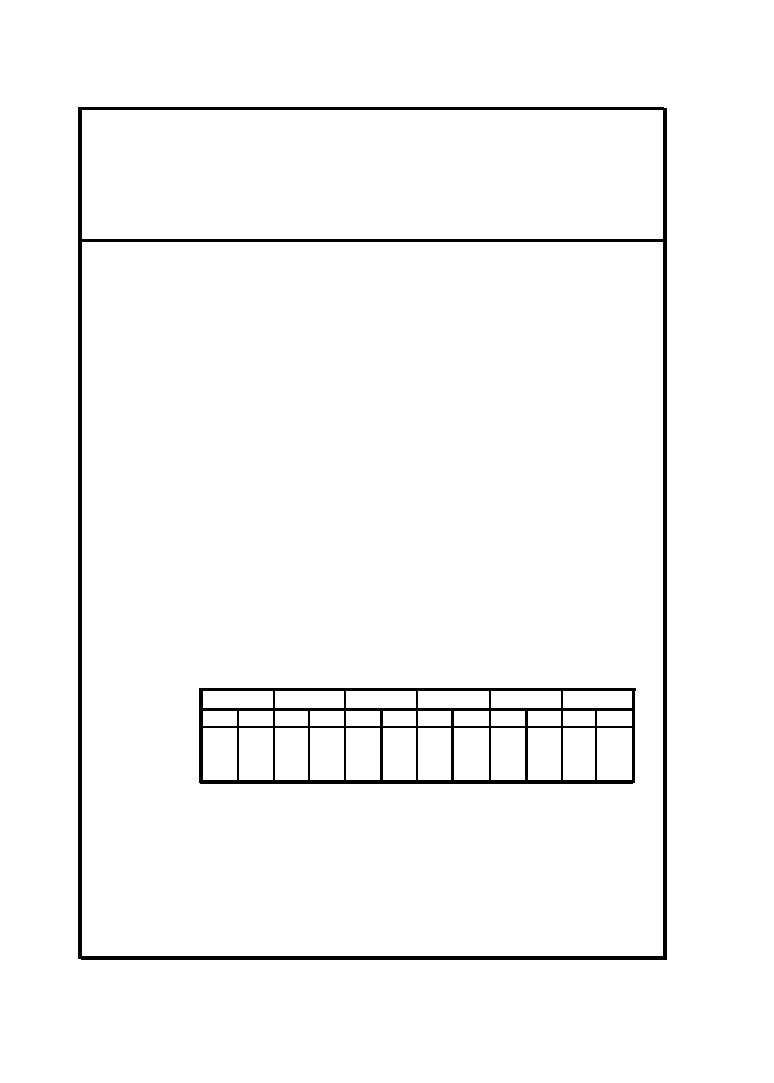

TRUCK WANDERS OR PULLS TO ONE SIDE ON LEVEL PAVEMENT.

NOTE: Check tire pressure when tires are cold.

Step 1. Check tire pressure.

M916

M918

M919

M920

M915

M917

Front Rear Front Rear

Front Rear Front Rear Front Rear Front Rear

100

75

50

50

95

50

75

50

90

50 100 50

Empty

65

50

90

60 100 50

50

85

60

50

90

1/2 Payload 80

50

100

90 100 90

80

90 100

90

Full Payload 95

70

95

Step 2. Check to make sure that all tires are of the proper size and type.

If tires are not properly matched, and if more than one tire is

involved, notify Organizational Maintenance. If only one tire

is improper and the spare tire is of the correct size and type,

replace improper wheel and tire assembly with the spare and

notify Organizational Maintenance that a replacement is

needed.

Step 3. Check for loose or damaged steering gear/linkage.

If you find evidence of any problems, notify Organizational

Maintenance.

3-12 Change 3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |