|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-1740-200-14

brackets for frame mounted components are extra heavy

1-54. MECHANICAL TRANSMISSION.

to provide required tractor weight, heavy duty service life

and stability for mounted components. Medium duty,

1-55. The mechanical transmission (10), attached to the

non-quick release pintle assemblies are mounted on the

rear of the hydraulic transmission, is a standard,

front and rear of the tractor.

commercial, five-speed gearbox with second through fifth

gear synchronized. Gear selection is made by manual shift

after disengaging the clutch.

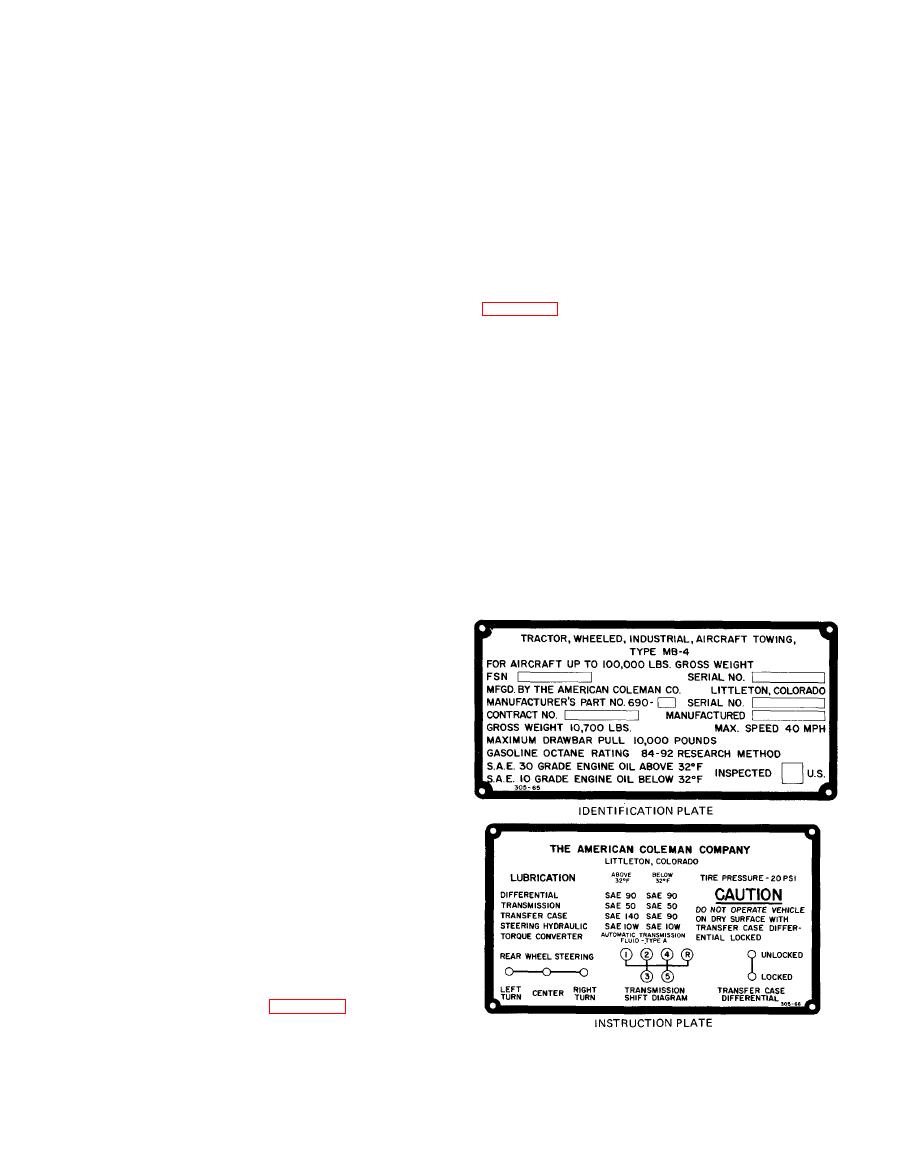

1-67. IDENTIFICATION AND INSTRUCTION

PLATES.

1-56. PROPELLER SHAFT INSTALLATION.

1-68. The type MB-4 towing tractor identification plate

1-57. Standard commercial propeller shafts connect the

transmission to the transfer case input shaft and connect

number and serial number, manufacturer name and

the front and rear output shafts of the transfer case with

address, manufacturer's part number and serial number,

the front and rear axles respectively.

contract number, manufactured date, gross weight,

maximum speed, maximum drawbar pull, gasoline octane

1-58. TRANSFER-TRANSMISSION ASSEMBLY.

rating, engine oil grade for above and below 32F

stamp impression. The instruction plate provides

1-59. The transfer-transmission assembly (11), sometime

applicable data.

referred to as the transfer case, is a single-speed gearbox

incorporating a manually-locking type center differential

between the front and rear output shafts. The center

1-69. DEVIATIONS IN MODELS.

differential action can be locked out by means of a lever

located to the driver's right. The transfer-transmission

assembly further multiplies the engine torque and

1-70. This manual covers only the type MB-4 Towing

transfers it to the front and rear axles through the

Tractor, Model Number G-40, part numbers 690-lB and

propeller shafts.

690-1B1. Existing unit differences shall be designated C

or D code.

1-60. BRAKE SYSTEM.

1-61. The service brake system (12) uses hydraulically

operated brake shoes and incorporates a vacuum booster.

The system has sufficient capacity to lock the wheels

when the brakes are applied at a maximum speed of 30

mph on dry concrete.

1-62. VACUUM BOOSTER. The vacuum booster is

controlled by hydraulic pressure developed within the

brake master cylinder of the vehicle.

1-63. AXLE INSTALLATION.

1-64. The front and rear axles (13) are identical, driving,

center-point steering type to reduce steering effort. The

one-piece axle shaft is easily removed without wheel

disassembly to facilitate quick removal of the axle

differential carrier assembly, which is a commercial,

high-production assembly.

1-65. FRAME AND BRACKETS ASSEMBLY.

1-66. The frame rails (14, figure 1-2) are made of

structural channel to provide strength and rigidity for the

tractor. Heavy frame end plates provide additional rigidity

AV 008935

and stable mounting for the counterweights. Various

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |