|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

CYLINDER BLOCK REPAIR (CONT)

3.

Using straightedge and feeler gage, check warpage of top of crankcase at 1-in. intervals along length.

Maximum allowable warpage cannot exceed 0.0007 in. (0.17 mm). If warpage exceeds maximum limit,

tag crankcase for repair.

4.

Using straightedge and feeler gage, check warpage of top of crankcase at 1-in. intervals along width.

Maximum allowable warpage cannot exceed 0.0012 in. (0.030 mm). If warpage exceeds maximum limit,

tag crankcase for repair.

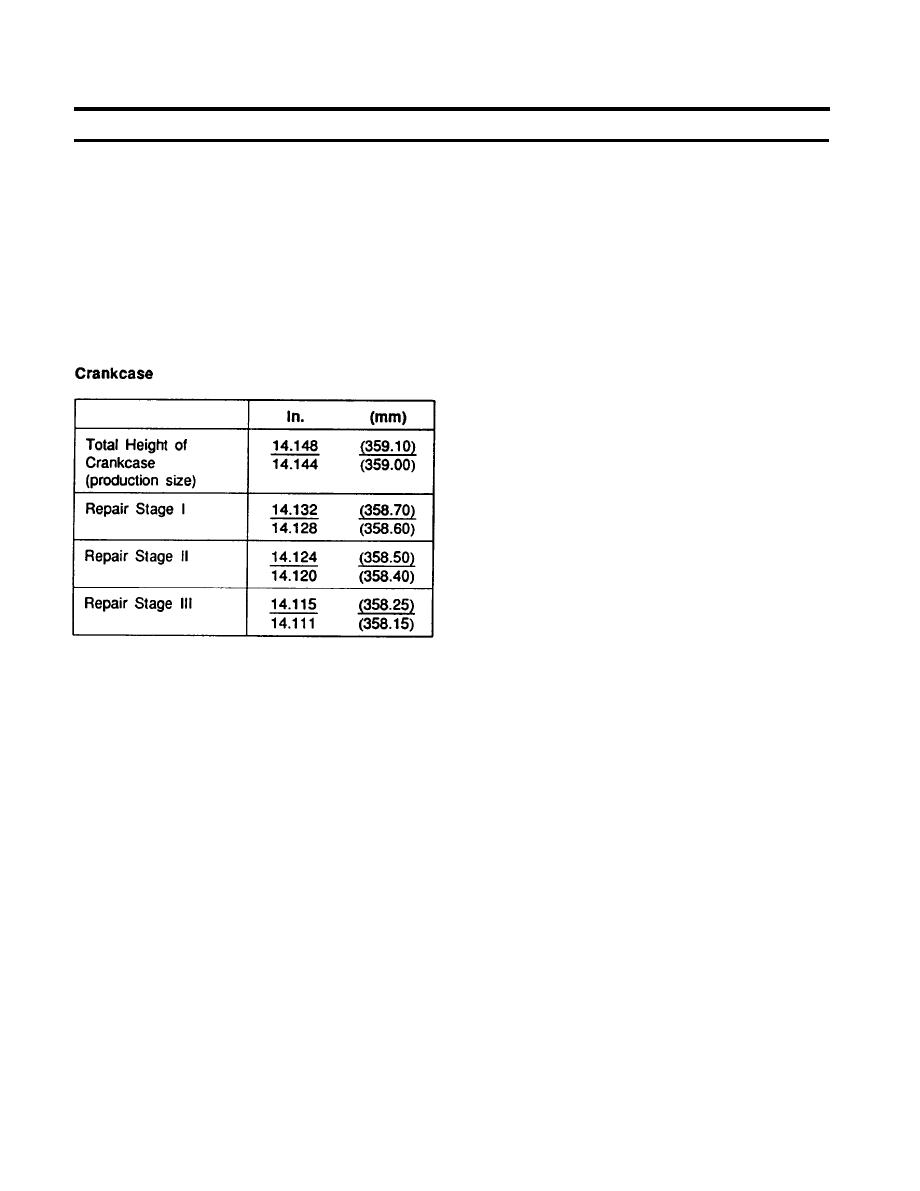

Measure total height of crankcase and refer to following table. If measurement is between repair

5.

stages, tag crankcase for repair. If measurement is less than 14.11 in. (358.15 mm), replace

crankcase.

Inspect top of crankcase for peaks and valleys. If any are present, measure distance between each

6.

peak and valley. Acceptable depth of each valley is 0.0001-0.0002 in. (0.003-0.005 mm). If maximum

depth is exceeded, tag crankcase for repair. if repair would cause total height to be less than allowable

in step 5, replace crankcase.

7.

Inspect honing pattern of each cylinder bore. if pattern has been even slightly destroyed, tag crankcase

for repair.

13-50

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |