|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

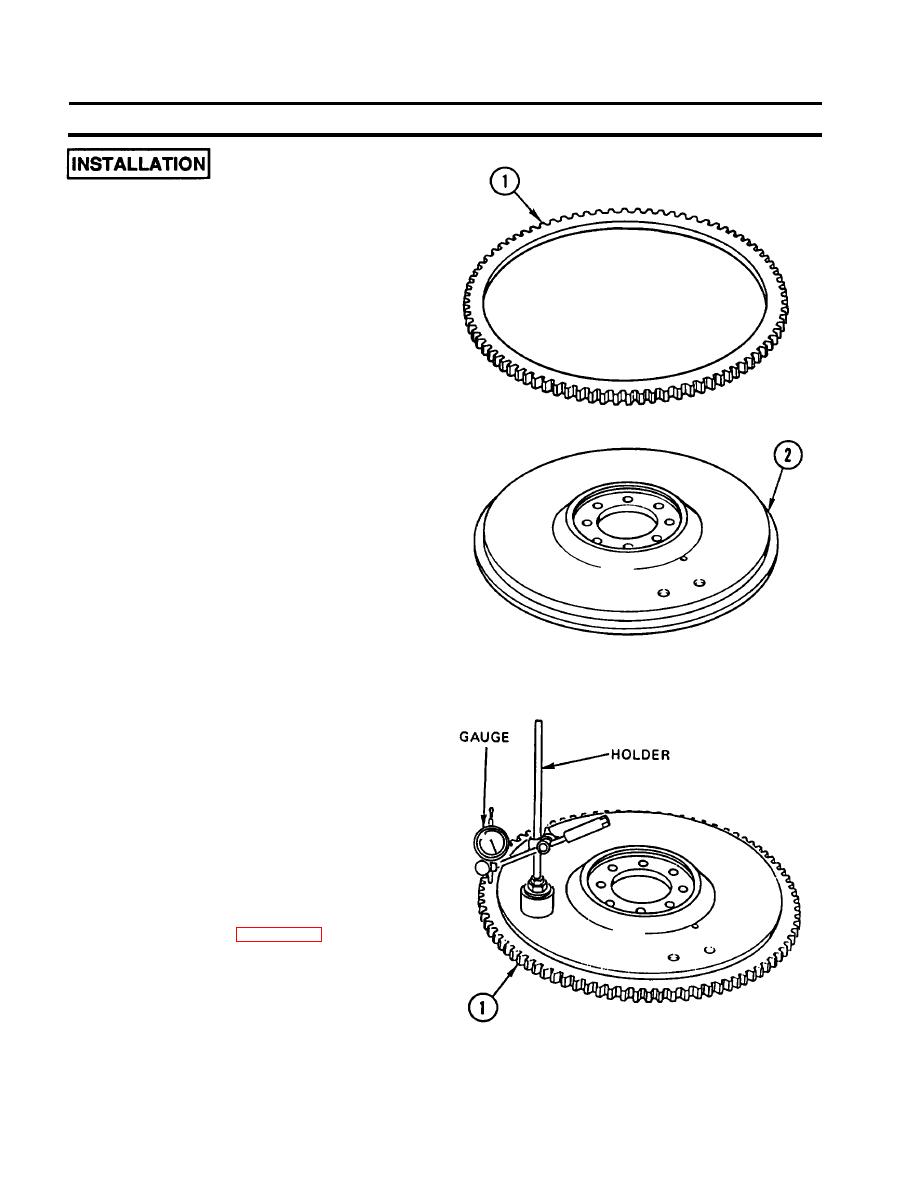

FLYWHEEL RING GEAR REPLACEMENT (CONT)

1.

A P P L Y COAT of TEMPERATURE

INDICATOR every few inches on outer edge

of ring GEAR (1).

2.

H E A T ring GEAR (1) until temperature

indicator turns to LIQUID. HEAT from INSIDE

diameter at 400 F (204C).

PRESS ring GEAR (1) onto ffywheel (2) with

3.

r e c e s s in ring gear (1) facing flywheel

shoulder.

4.

USING GAUGE and HOLDER, CHECK lateral

RUNOUT of ring gear (1). Runout CANNOT

be more than 0.020 in. (0.5 mm).

NOTE

Follow-on Maintenance:

Install flywheel (page 13-25).

13-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |