|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

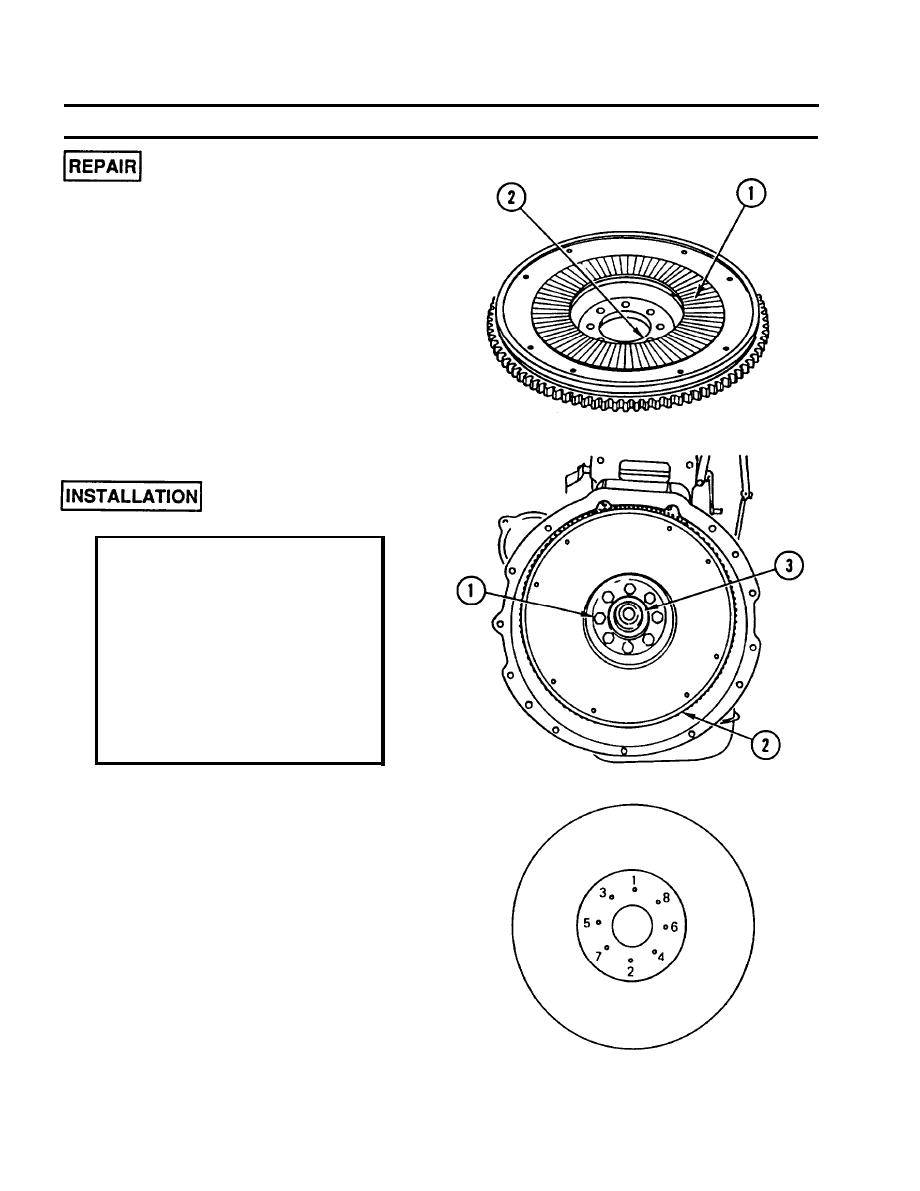

FLYWHEEL REPLACEMENT AND REPAIR (CONT)

Prior to machining flywheel friction surface (1),

1.

measure distance from friction surface (1) to

mounting area (2). Record measurement.

Machine flywheel friction surface (1) to repair

2.

any damage. Do not exceed dimensional limit

of 0.0394 in. (1 mm).

3.

M a c h i n e mounting area (2) to maintain

measurement taken-in step 1.

WARNING

Adhesive causes immediate

bonding on contact with eyes,

skin, or clothing and also gives

off harmful vapors. Wear

p r o t e c t i v e goggles and use in

w e l l - v e n t i l a t e d area. If adhesive

g e t s in eyes, try to keep eyes

o p e n ; flush eyes with water for

1 5 minutes and get immediate

medical attention.

1.

APPLY COAT of SEALING COMPOUND to

eight SCREWS (1). INSTALL FLYWHEEL (2)

on crankshaft flange (3) and INSTALL eight

SCREWS (1). TIGHTEN SCREWS to 22-29

Ib-ft (29-39 N.m) in sequence shown.

13-26

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |