|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM

5-2420-224-34

FRONT

LOADER/FORKLIFT

CONTROL

VALVE

AND

BRACKET

REPLACEMENT

AND

ADJUSTMENT

(CONT)

NOTE

Pressure gage must be calibrated. If not, performance of front loader/forklift circuits and

tool circuits will not be correct.

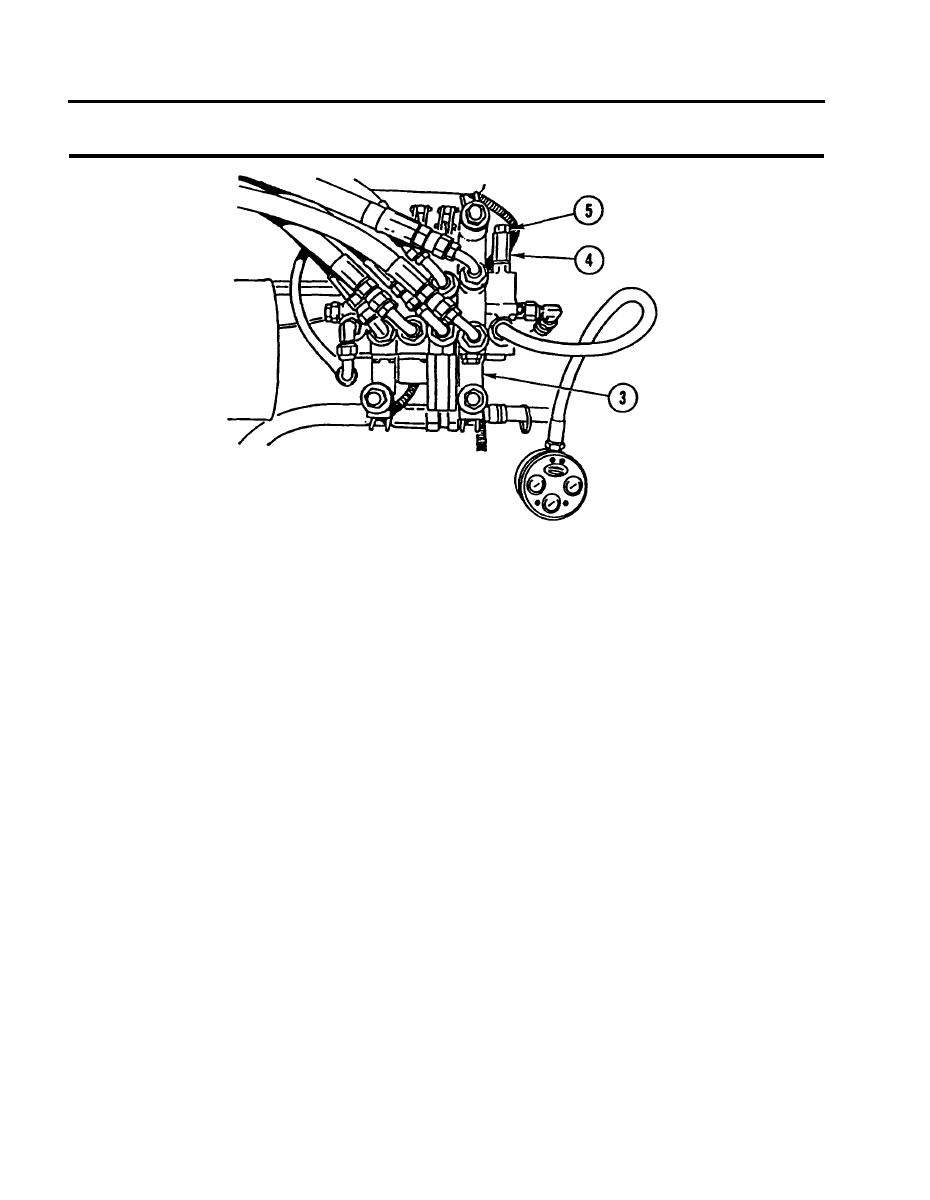

6.

Operate control valve (3) until oil reaches operating temperature (120F) by performing the following:

a. Start and run engine at 2000 rpm.

b. Move bucket control lever into rollback position and hold for 15 seconds.

c.

Place control lever in neutral for 30 seconds.

d. Repeat until oil in hydraulic system is at operating temperature.

Keep engine running at 2000 rpm.

7.

8.

Move bucket control tilt lever into rollback/tilt back position. Hold bucket/forks in this position and read

pressure gage.

Pressure reading must be set at 2450 psi. If pressure reading is not correct, repeat steps 7 and 8

9.

while holding bucket control lever in dump/forward tilt position. If pressure reading is still not correct,

adjust main relief valve by performing the following:

a.

Loosen lock nut (4) on main relief valve adjusting screw (5).

b. Turn adjusting screw (5) into main relief valve to increase pressure setting; turn adjusting

screw (5) out of main relief valve to decrease pressure setting.

c. Tighten lock nut (4).

10.

C h e c k pressure setting for 2450 psi.

Adjust or repair main relief valve as necessary.

11-36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |