|

| |

TM 5-2420-222-34

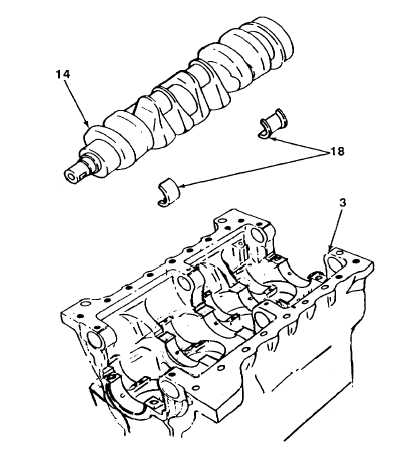

3-8.CRANKSHAFT MAINTENANCE (Con’t).

7.

Using ball-peen hammer and wood block, tap crankshaft (14) to the rear of engine block (3). Aline front flanges of

upper and lower sleeve bearing halves (9 and 18).

8.

Using ball-peen hammer and wood block, tap crankshaft (14) to the front of engine block (3). Aline rear flanges of

upper and lower sleeve bearing halves (9 and 18).

9.

Torque screws (2) to 85 lb.-ft. (115 N•m).

NOTE

Engine has four connecting rod bearing caps. Installation of all four is the same.

One Is shown. Repeat steps 10 through 15 for remaining connecting rod bearing

caps.

10. Install screw (15) in end of crankshaft (14). Using screw, rotate crankshaft until mating journal of desired connecting

rod bearing cap (5) is accessible.

11. Slide upper sleeve bearing half (10) in place on connecting rod (11). Ensure that tang on upper sleeve bearing half fits

in locking groove of connecting rod. Coat parts with engine oil.

12. Pull connecting rod (11) with assembled parts down into position on crankshaft (14).

13. Slide lower sleeve bearing half (4) in place in connecting rod bearing cap (5). Ensure that tang on lower sleeve

bearing half fits in locking groove of connecting rod bearing cap. Coat parts with engine oil.

TA701257

3-57

|