|

| |

TM5-2420-222-34

14-10

BACKHOE STABILIZER AND BUCKET VALVES REPAIR (Con’t).

b.

CLEANING AND INSPECTION

WARNING

• Dry cleaning solvent, P-D-680, Is toxic and flammable. Always wear protective

goggles and gloves, and use only In a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point is 100F-138F (38°C-59°C). If

you become dizzy while using cleaning solvent, Immediately get fresh air and

medical help. If solvent contacts eyes, Immediately wash your eyes and get

medical aid.

• Compressed air used for cleaning or drying purposes, or for clearing restrictions,

should never exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield,

gloves, etc.) and use caution to avoid Injury to personnel.

1.

Clean valve body with rags dampened with dry cleaning solvent. Dry thoroughly with compressed air.

2.

Clean three fluid flow restrictors and valve with dry cleaning solvent and rags. Dry thoroughly with compressed air.

Ensure that holes are free of material and dirt.

3.

Clean all other metal Darts with dry cleaning solvent. Dry thoroughly with compressed air.

5.

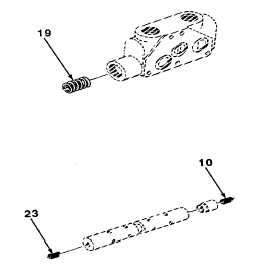

Inspect spool spring (19) for cracks, breaks, and

abnormal bends. Using spring tester and torque

wrench, apply 27 lb (120 N) of force and measure

compressed length of spring. Compressed length

must be 1.1875 in. (30.1625 mm).

6.

Inspect springs (10 and 23) for cracks, breaks,

and abnormal bends. Using portable spring

resiliency tester and machinist’s rule, apply 8 oz

(2.2 N) of force and measure compressed length

of springs. Compressed length must be 0.8125

in. (20.637 mm).

TA701582

14-52

|