|

| |

TM 5-2420-222-34

14-2.

ACCUMULATOR ASSEMBLY MAINTENANCE (Con’t).

9.

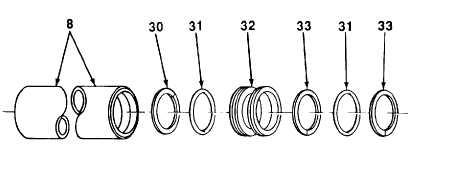

Slide piston (32) with assembled parts out of hydraulic cylinder (8).

10.

Remove two packing retainers (33), preformed packings (31), and packing retainer (30) from piston (32). Discard

preformed packings and packing retainers.

c.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, Is toxic and flammable. Always wear protective

goggles and gloves, and use only In a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open flame

or excessive heat. The solvent's flash point Is 100°F-1380F (380C-590C). If you

become dizzy while using cleaning solvent, Immediately get fresh air and medical

help. If solvent contacts eyes, Immediately wash your eyes and get medical aid.

1.

Clean all metal parts with dry cleaning solvent and rags. Dry thoroughly with clean, dry rags.

2.

Inspect all metal parts for cracks, breaks, and abnormal bends.

3.

Inspect end cap and cap for damaged threads.

4.

Inspect Inner diameter of hydraulic cylinder for scratches, nicks, and excessive wear.

5.

Inspect end cap, cap, control valve body, and piston for scratches, nicks, and excessive wear.

6.

Inspect retaining rings for deformity or breaks.

d.

REPAIR

Restore damaged end cap (5) or cap threads using screw threading set.

e.

ASSEMBLY

1.

Coat new gasket (26) with hydraulic fluid. Install in end cap (5).

2.

Install sleeve spacer (25), control valve body (24), spring (23), and seat (22) in place on end cap (5).

TA701546

14-10

|