|

| |

TM 5-2420-222-34

8-10.

GEAR SHIFTERS AND SHIFTER SHAFTS MAINTENANCE. (Con’t)

b.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, Is toxic and flammable. Always wear protective

goggles and gloves, and use only In a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point Is 100°F-138°F (38°C-59°C). If

you become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts eyes, Immediately wash your eyes and get

medical aid.

1.

Clean all metal parts with dry cleaning solvent. Dry thoroughly with clean, dry rags.

2.

Inspect ball bearings (see TM 9-214).

3.

Inspect shifter forks, shafts, remote control lever, and pin for cracks, breaks, bends, grooves, and excessive wear.

Replace if defective.

4. Inspect four springs for cracks, bends, and breaks. Using spring tester, measure free length of springs. Free length

must be 0.960 in. (24.384 mm).

5.

Using spring tester and torque wrench, compress springs to 0.640 in. (16.256 mm) and read compression force on

torque wrench. Compression force must be 13-17 lb.-ft. (18-23 N•m).

6.

Inspect all other metal parts for cracks, breaks, and abnormal bends.

7.

Inspect shifter forks for damaged threads.

c.

REPAIR

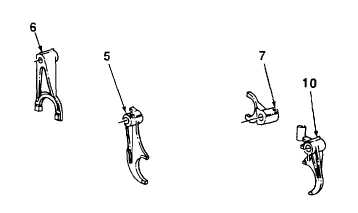

Restore damaged shifter fork (5, 6, 7, and 10)

threads using screw threading set.

d.

INSTALLATION

1.

Install pin (28) in transmission (11).

2.

Install expansion plug (21) and spring (22) in

transmission (11).

3.

Tap new spring pin (24) in transmission (11)

and expansion plug (21).

TA701389

8-50

|