|

| |

TM 5-2420-222-34

7-2.

ENGINE STARTER REPAIR (Con’t).

CAUTION

Do not touch commutator brush surface or shaft bearing surface with test probes.

This may cause arcing which could damage surfaces.

12.

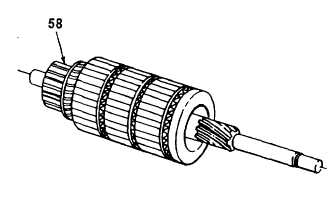

Inspect commutator (58) for roughness,

burrs, pitting, burning, and loose solder

joints.

13.

Using V-blocks and dial indicator, check

commutator for high mica. Undercut depth

must be 0.031 in. (0.787 mm).

14.

Using armature test set, check commutator

for short circuits and open or grounded

windings.

Short

circuits

and

open

or

grounded windings are not allowed.

15.

Inspect coil for frayed, worn, and damaged

insulation. Using multimeter, check coil for

open circuit. No open circuit is allowed.

16.

Using multimeter, check for grounding between main housing and coil. No continuity between main housing and

coil is allowed. Ground may be caused by worn insulation or metal particles trapped between coil and main

housing.

17.

Rotate drive pinion in both directions. Pinion should rotate smoothly with slight drag in one direction and lock up in

the other direction.

c.

REPAIR

1.

Restore any damaged threads using screw threading set.

2.

Remove rough or burred areas on commutator (58) using fine abrasive paper. Commutator should be smooth

and shinny.

3.

Using soldering gun and tin alloy solder, solder loose solder joints or open windings on commutator (58).

4.

If commutator (58) is out-of-round, turn commutator down on lathe until round and smooth.

5.

If mica clearance is less than allowed, undercut mica to depth of 0.031 in. (0.787 mm) using electrically operated

armature mica undercuts.

6.

If short circuit is found in commutator (58), clean grooves between bars.

TA701349

7-21

|