|

| |

TM 5-2420-222-34

3-12.

VALVE MAINTENANCE.

This Task Covers:

a.

Removal

c.

Repair

b.

Cleaning and Inspection

d.

Installation

Initial Setup:

Equipment Conditions:

Materials/Parts:

•

Rocker arm, shaft, and pushrods removed (see

•

Carbon removing compound (Item 8, Appendix B)

paragraph 3-13).

•

Prussian blue dye (Item 14, Appendix B)

•

Cylinder head removed (see paragraph 3-6).

•

Engine oil (Item 25, Appendix B)

•

Rags (Item 28, Appendix B)

Tools/Test Equipment:

•

Dry cleaning solvent (Item 31, Appendix B)

•

General mechanic's tool kit

General Safety Instructions:

•

Field automotive shop set

•

Dry cleaning solvent is flammable and must not be used

near open flame. Use only in a well-ventilated area.

•

Compressed air used for cleaning purposes should never

exceed 30 psi (207 kPa).

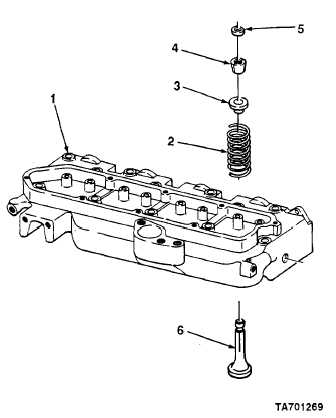

NOTE

All intake and exhaust valves are maintained the same way. One Is shown.

Repeat procedure for other valves as required

a.

REMOVAL

1.

Remove valve seat (5) from top of valve (6).

2.

Using valve spring lifter, compress valve spring

(2).

CAUTION

Valve may be loose and could fall out

of cylinder head. Ensure that valve

does not fall out or damage to parts

may result.

3.

Remove exhaust valve cap (3) from valve (6)

and valve lock (4).

4.

Remove valve spring lifter, valve lock (4), and

spring (2) from cylinder head (1) and valve (6).

3-77

|