|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

WINCH ASSEMBLY REPAIR - CONTINUED

0245 19

ASSEMBLY - CONTINUED

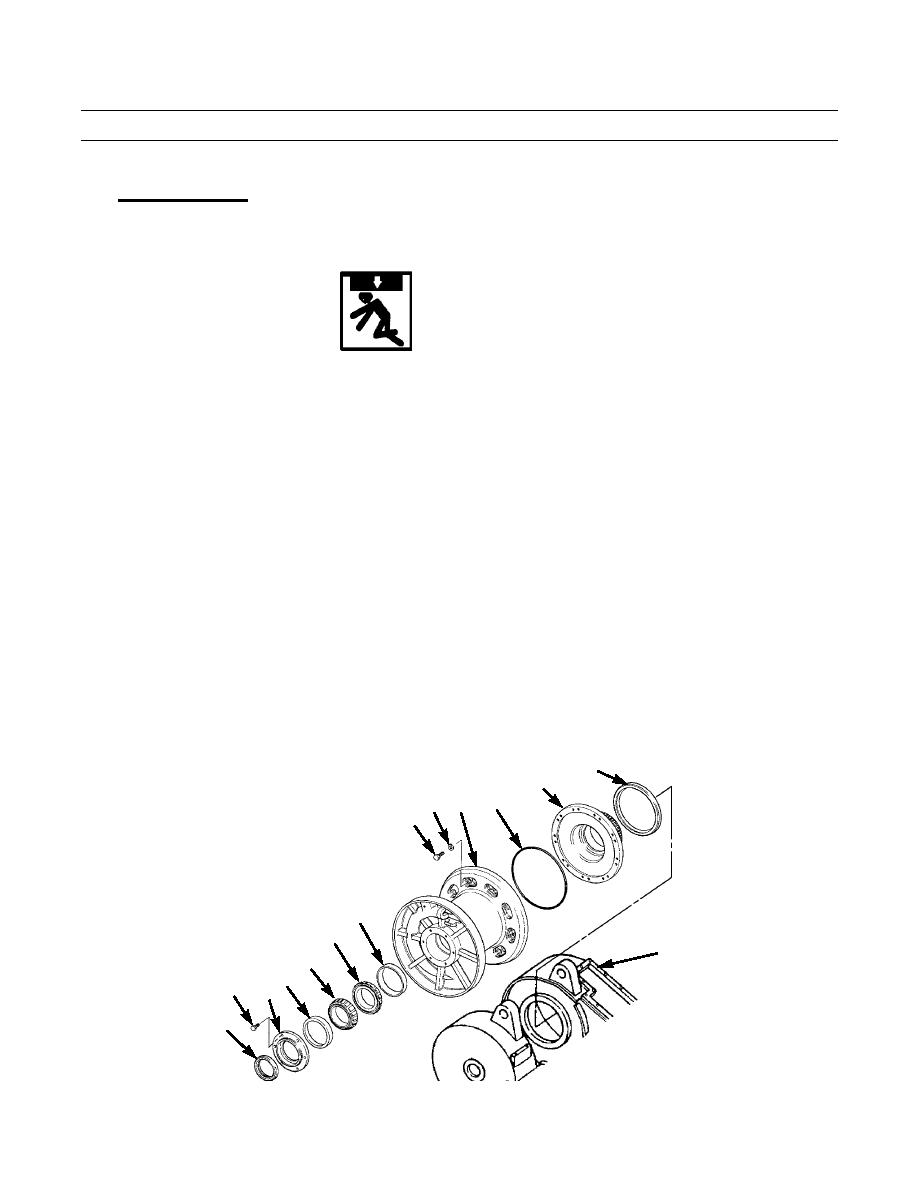

Install Winch Drum.

7.

a.

Reposition case (5) with input shaft opening facing downward.

b.

Install new seal (54) in case (5).

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may result in injury or death.

NOTE

Drum support flange weighs 81 lb (38 kg).

c.

Fasten lifting equipment to drum support flange (33) and position drum support flange in case (5).

d.

Install lifting link in end of drum support flange (33) inside case (5). Fasten wire from lifting link to boss on out-

side of case.

CAUTION

Ensure surfaces on retainer and drum are clean before installing bearing cups. Failure to clean bearing cup

surfaces may cause premature bearing failure.

e.

Clean bearing cup surfaces on retainer (47) and drum (30).

f.

Install bearing cup (51) in retainer (47). Install bearing cup (52) in drum (30).

g.

Install new seal (48) in retainer (47).

h.

Install bearing cones (49 and 50) in drum (30).

54

33

53

32 30

31

52

50

5

49

51

46

47

48

421-0213

Change 1

0245 19-36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |