|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

TURBOCHARGER REPAIR - CONTINUED

0245 13

CLEANING AND INSPECTION

WARNING

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low toxic

material. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in

well-ventilated areas. Keep away from open flames and other sources of ignition.

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. DO NOT direct compressed air against human skin. Failure to

follow this warning may result in serious injury. Make sure air stream is directed away from user and

other personnel in the area. To prevent injury, user must wear protective goggles or face shield.

1.

Clean all components and surfaces with solvent cleaning compound.

2.

Dry components with compressed air.

3.

Inspect all components for wear, pitting, cracks or corrosion IAW WP 0241 00.

4.

Replace damaged components.

5.

Inspect oil passages to make sure they are clean and unobstructed.

6.

Inspect oil passages for corrosion, pitting and damage.

7.

Replace components as necessary.

ASSEMBLY

1.

Coat all components with a thin film of clean oil.

28

2

APPLY HIGH TEMPERATURE

2.

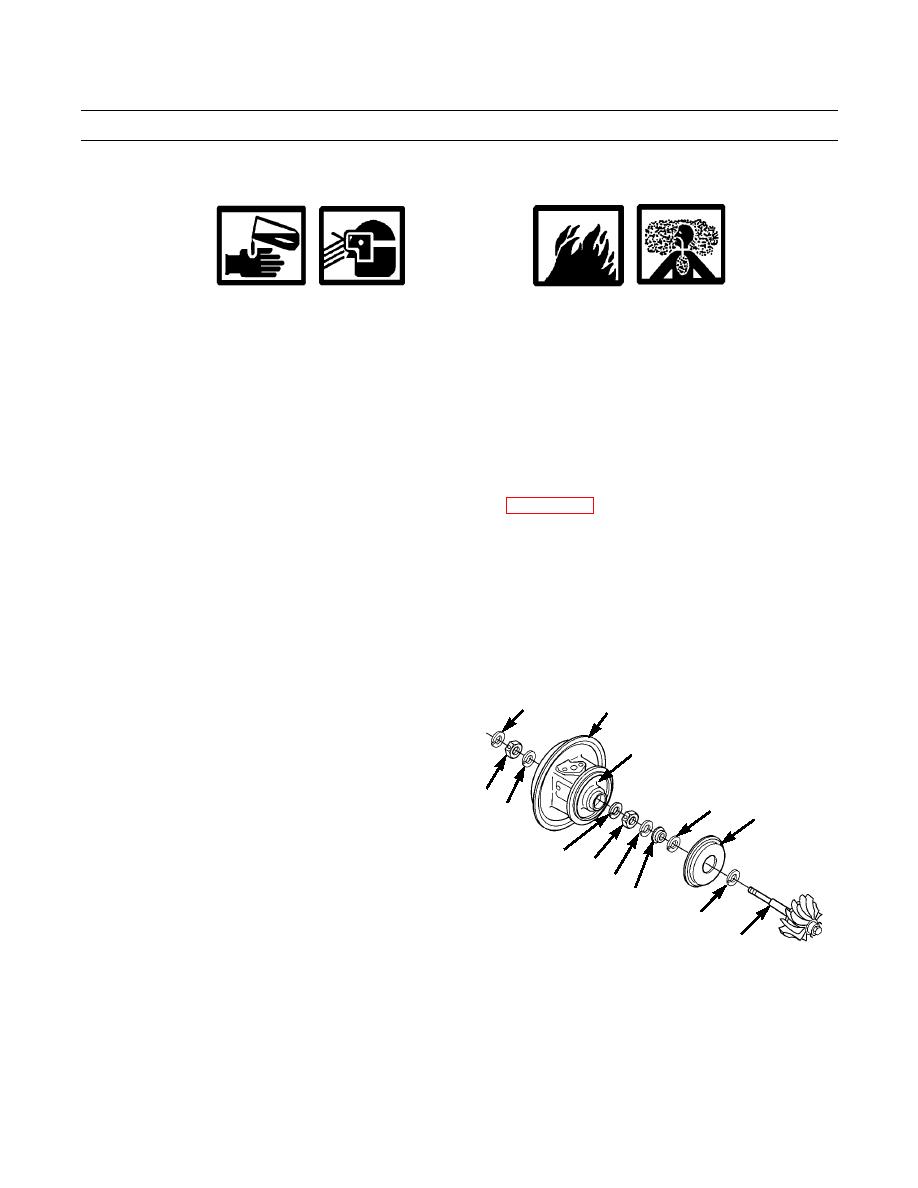

Install snap ring (16) with round side facing out.

GREASE HERE

3.

Install new bearing (15) and snap ring (14) with round

side facing out.

29

12

11

30

4.

Install new sleeve (13) and new snap ring (12).

5.

Install snap ring (30) into cartridge (2) with round side

16

facing out.

15

14

13

6.

Install bearing (29) into cartridge (2). Install snap ring

10

(28), with round side toward bearing, into cartridge

(2).

9

421-0240

7.

Fill seal groove to at least one-half depth with high

temperature grease. Install new seal (10) onto shaft of

turbine wheel assembly (9).

8.

Place shroud (11) on small side of cartridge (2). Install

turbine wheel assembly (9) through small side of car-

tridge (2).

Change 1

0245 13-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |