|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

HYDRAULIC PUMP REPLACEMENT - CONTINUED

0199 00

INSTALLATION

CAUTION

Wipe all sealing surfaces and hose connections clean and dry prior to installation. Contamination of

hydraulic system could result in premature failure.

NOTE

Lightly coat new O-rings with clean oil before installation.

1.

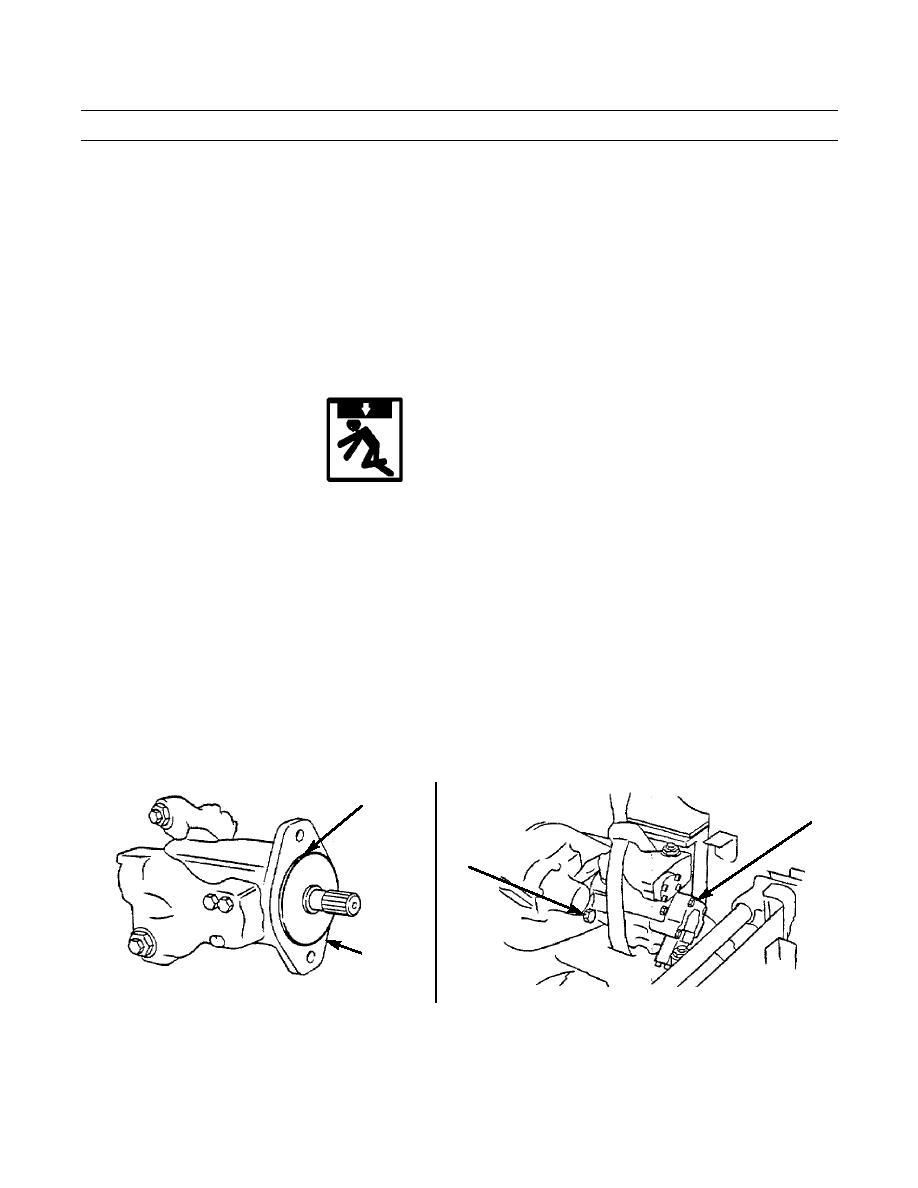

Install new O-ring (18) on hydraulic pump (15).

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may result in death or injury to

personnel.

CAUTION

Ensure splines on pump shaft are aligned with internal splines on engine auxiliary drive gear.

NOTE

Hydraulic pump weighs 50 lb (23 kg).

2.

Attach a nylon sling and a suitable lifting device to hydraulic pump (15) and lift assembly into position on engine auxil-

iary drive cover.

3.

Secure hydraulic pump (15) on engine auxiliary drive cover with two flatwashers (17) and capscrews (16).

18

15

16,17

15

387-502

387-501

4.

Connect hose (13) on underside of elbow (14) on hydraulic pump.

5.

Install new O-ring (12) and large hose (11) on bottom of hydraulic pump with split flange (10), four capscrews (8) and

flatwashers (9).

0199 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |