|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

TRACK ASSEMBLY REPLACEMENT - CONTINUED

0143 00

REMOVAL - CONTINUED

NOTE

Drawbar pin (4) must have contact with track bushing when sprocket (5) is turned in reverse.

Position drawbar pin evenly.

4.

Install drawbar pin (4) between teeth of sprocket (5).

5.

Start machine and move track forward and backward to loosen track. If track does not loosen, proceed to step 6.

WARNING

Keep all personnel clear of front and rear of machine. Track moves fast and uncontrolled if separation

occurs. At least 20 ft of clearance is required in front. Failure to follow these precautions could result in

serious injury or death.

6.

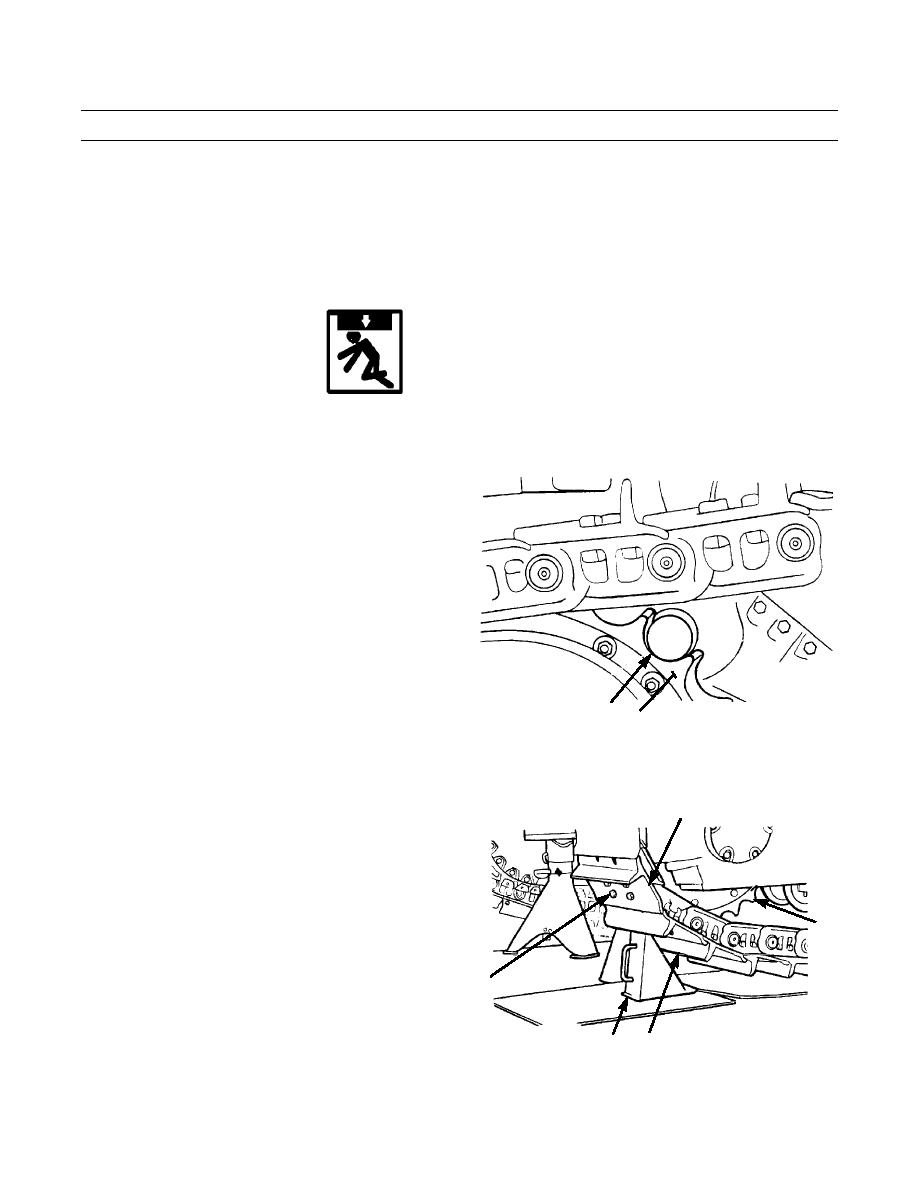

Move machine to the rear until slug (4) is in 9 o'clock

position (3 o'clock position for left-hand track) to put

tension to the rear against force of recoil spring and

push grease out of vent holes.

7.

Move machine forward to release tension on track.

8.

Remove slug (4) from teeth of sprocket (5).

4

387-595

5

9.

Move track until master link (6) is in 8 o'clock posi-

6

tion (4 o'clock position for left-hand track) on

sprocket (5).

10.

Install track block (7) under track shoe (8) next to

master link (6) and move track until track shoe makes

contact with track block.

6

9

387-596

8

7

0143 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |