|

|||

|

|

|||

|

Page Title:

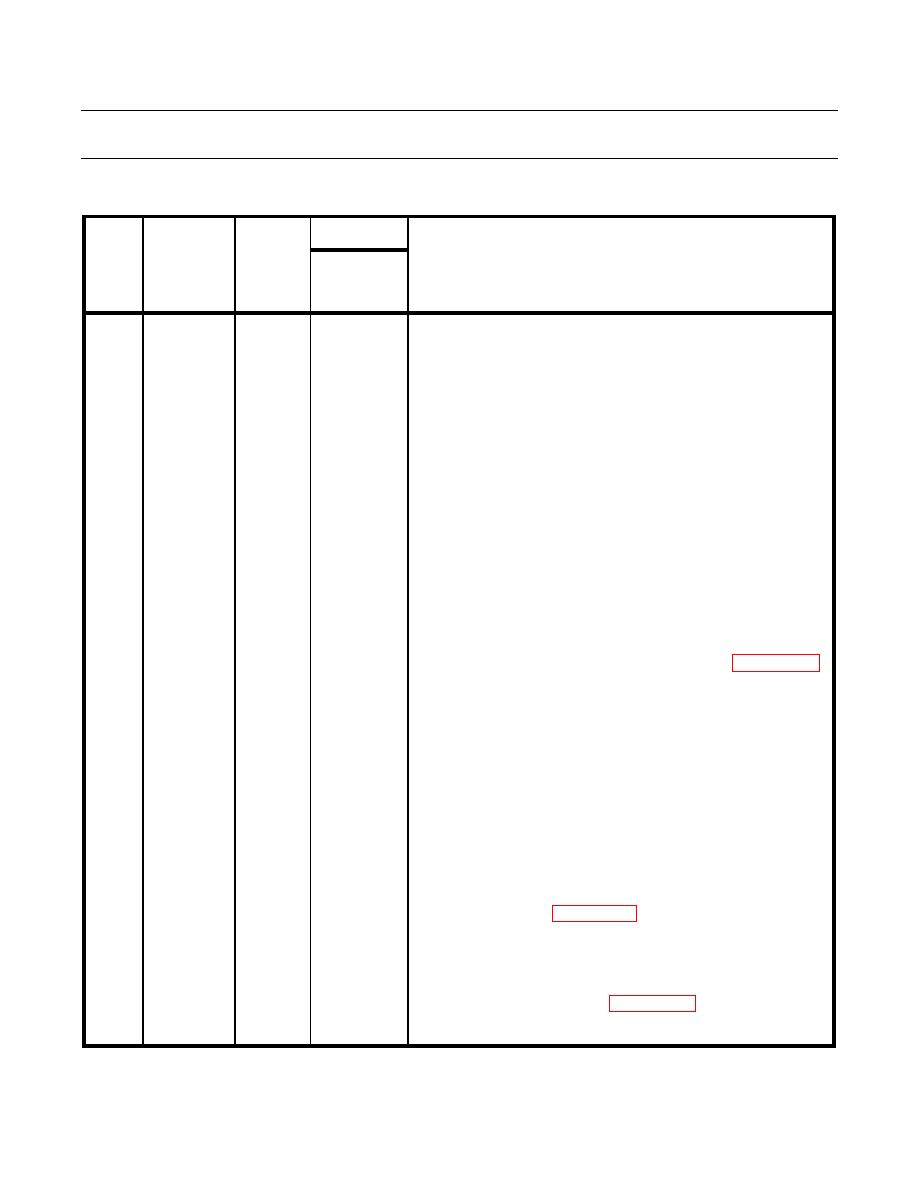

Table 1. Unit Maintenance Preventive Maintenance Checks and Services (PMCS) for the D7G Tractor. - Continued |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

UNIT MAINTENANCE PREVENTIVE MAINTENANCE CHECKS AND

SERVICES (PMCS) - CONTINUED

0010 00

Table 1. Unit Maintenance Preventive Maintenance Checks and

Services (PMCS) for the D7G Tractor - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NO.

INTERVAL

HOURS

SERVICE

PROCEDURE

24.1

a.

Visually inspect refrigerant system for air conditioning lubricant

leakage, corrosion and damage to lines, hoses and other compo-

(Con't)

nents.

b.

Visually inspect lowest points of fittings, hoses and lines for

indication of lubricant leakage.

c.

Using a refrigerant leak detector in accordance with the manu-

facturer's instruction manual, check for refrigerant leakage at

hose connections, fittings and areas where leakage might occur.

If leaks are indicated, notify Direct Support Maintenance.

25

1000 Hours

1.1 Hours Transmis-

a.

Inspect transmission control valves for leaks, wear or cracks

that could cause failure.

or Annual

sion Assem-

bly

b.

Inspect transmission body for cracks or loose capscrews that

could cause leaks.

c.

Inspect transmission shift linkage for bends, cracks and wear

that could cause failure.

d.

Perform complete transmission assembly service (WP 0107 00):

(1) Drain oil from transmission assembly.

NOTE

Breather is common to transmission and steering clutches/

final drives.

(2) Replace transmission breather.

(3) Replace transmission and steering clutch filter assembly.

(4) Clean transmission oil magnetic screen assembly and torque

divider suction screen and check for leaks.

(5) Refill transmission and check for leaks.

26

2000 Hours

or Annual

Lash

27

1000 Hours

0.5 Hours Final Drives

a.

Inspect final drives for evidence of oil leakage.

or Biennial

b.

Drain final drives and refill (WP 0124 00).

0010 00-11

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |