|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

6-27. Final Drive Pinion Group

a. Removal and Installation.

(1) Remove the steering clutch as outlined in

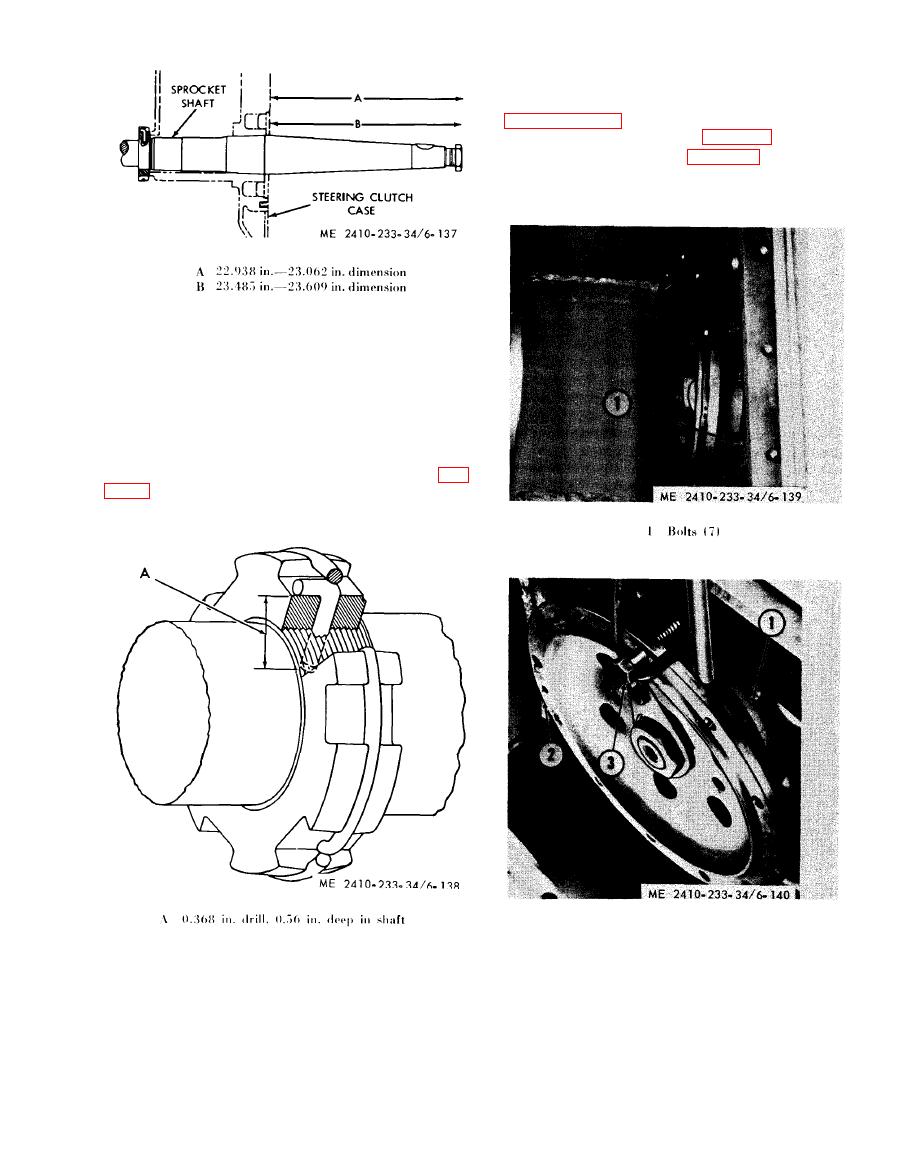

(2) Remove bolts (1, fig. 6-139).

(3) Insert a bolt (3, fig. 6-140) in one of the

steering clutch to pinion flange clearance holes and

attach a hoist for support.

installed.

(7) Maintaining the 55-60 tons pressure on

the shaft, tighten retaining nut with a spanner

wrench.

(8) When the retaining nut is securely

tightened, lock it in the following manner.

(9) n one of the notches in the retaining nut.

drill a 0. 368 inch diameter hole through the nut

and 0.56 inches deep into the sprocket shaft (A, fig.

lockring to hold it in place.

1 Cage

2 Flange

3 Bolt

d. Checking Sprocket Shaft. Check the final

drive sprocket shaft to determine if it is straight.

(4) Using a suitable pry bar, remove final drive

NOTE

pinion flange (2), bearing cage (1), inner bearing

If the sprocket shaft is bent more than the allowable

and final drive pinion as a unit from the steering

tolerance, shaft should be removed and a new shaft

clutch and bevel gear case.

installed.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |