|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

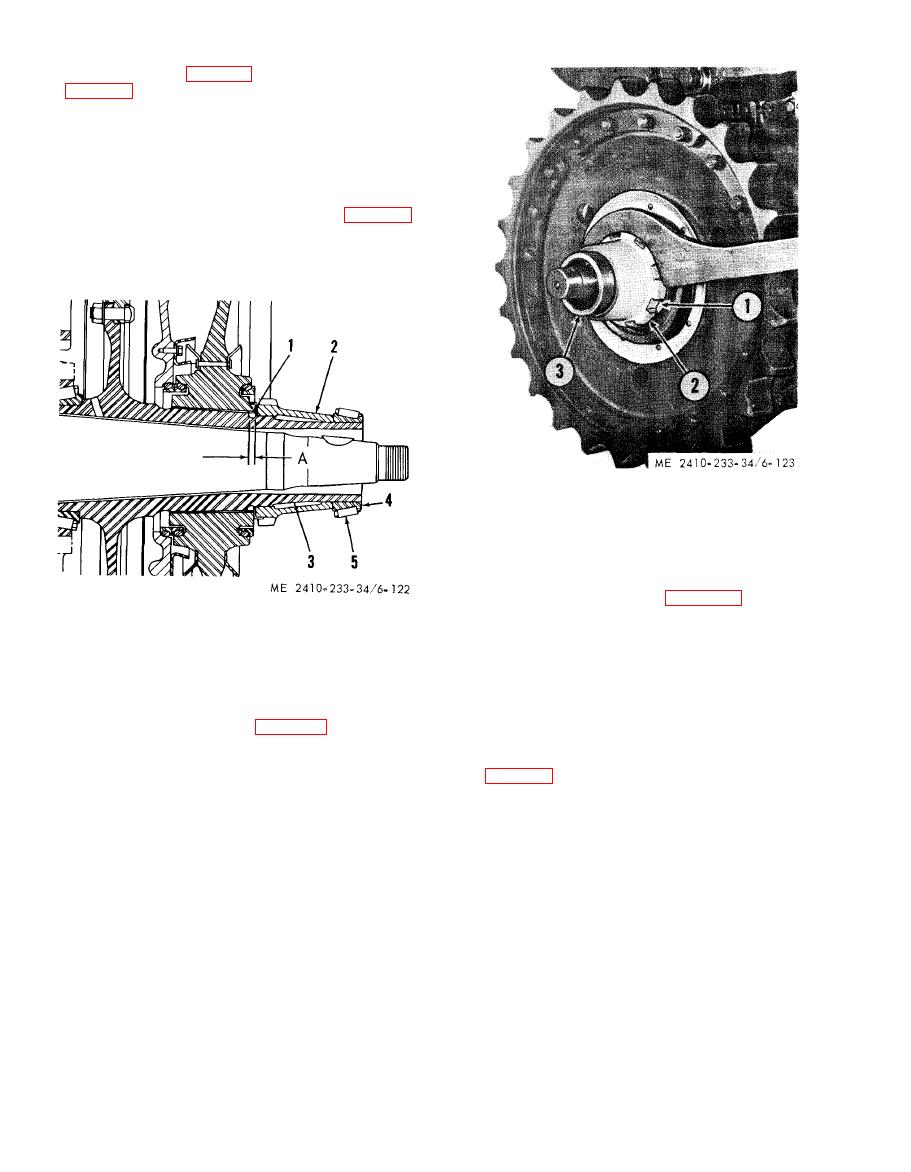

(f) Place ring (6) and sleeve (5) over adapter

(3) and hub (3, fig. 6-122) and connect adapter (2,

(g) Place the pump control in the pulling

position and apply a slight press to the sprocket.

Rock the sprocket back and forth to equalize the

load.

(h) Press the sprocket on to 60-65 tons.

(i) When a new sprocket or final drive hub

has been installed, measure distance (A, fig. 6-122)

between the end of the sprocket and the end of the

splines on the final drive hub. Distance (A) should

be 0.44-0.56 inches.

1

Lock

2

Nut

3

Hub

(1) Remove the installation tools and install

the metal floating ring seals (para 6-22).

b. Sprocket Segments.

1 Lock

2 Nut

(1) General. The segmented sprockets consist

3 Hub

of a hub with sprocket segments bolted into place

4 Bearing cone

around the hub. Sprocket segments can be replaced

A Dimension to be checked

without removing the hub from the tractor.

(2) Removal.

(a) Remove dirt guards to provide access to

sprocket segments.

spanner wrench, install sprocket retaining nut (2).

(b) Loosen track adjustment and insert pin

(k) After locking the retaining nut, heat

(1, fig. 6-124) in the last slot of the segment (3) just

outer bearing cone (preferably in oil) and drive it

behind the segment (2) to be replaced.

onto final drive gear hub (3) until it seats against

retaining nut (2).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |