|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Inspection.

(a) Inspect sprocket and sprocket hub

splines for damage and wear. lf the sprocket is

removed easily, the splines in one or both may be

worn and should be replaced.

(b) Inspect the sprocket segments for

damage and wear. Segments with teeth having

considerably more wear on one face than the other,

may be switched from one side of the tractor to the

other. If sprocket segments faces are worn 3/16

inch or more, replace sprocket. To prevent ac-

celerated wear, the sprocket segments must be

replaced in sets only.

corrosion, cracks, breaks, distortion or other

dam age. Replace a defective or damaged guard.

(3) Installation

120) make sure the splines are clean, dry, and free

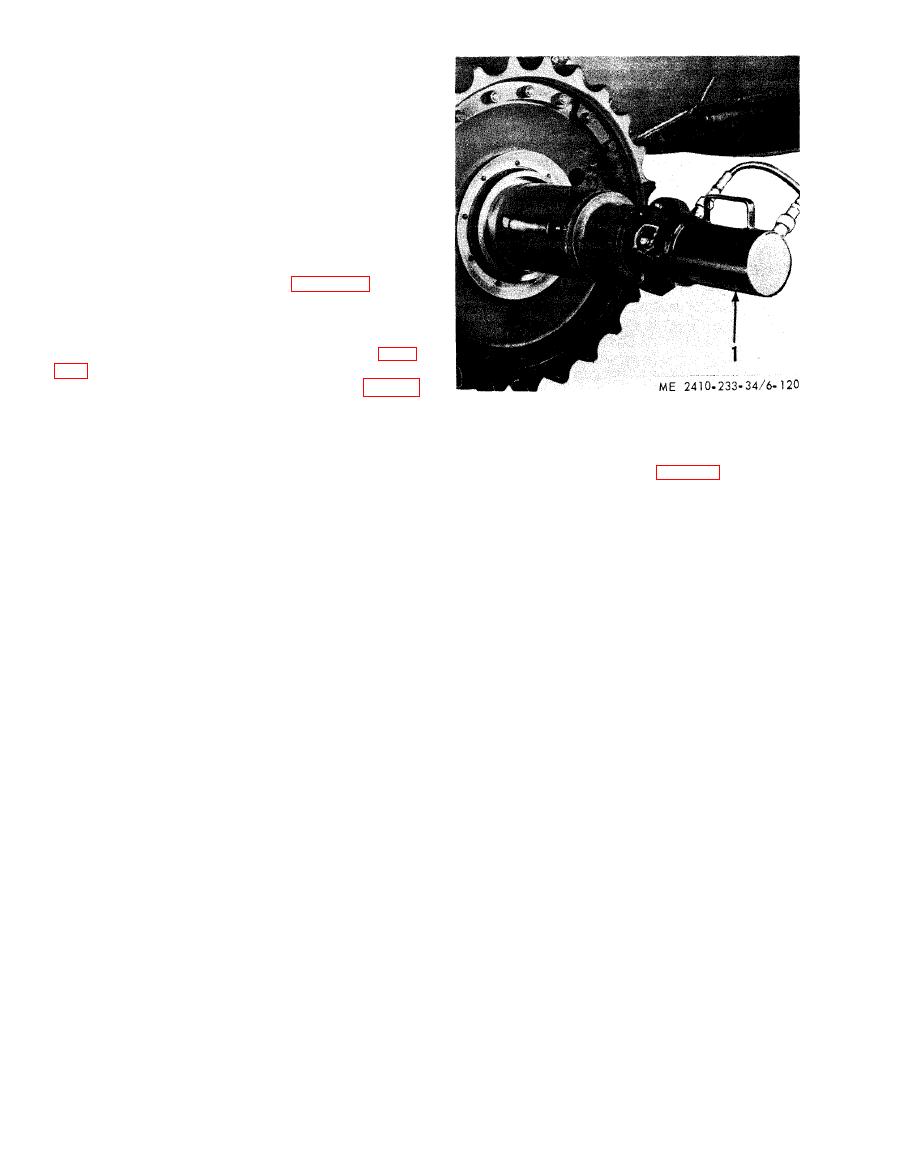

1 Cylinder group

of burrs. Set the sprocket on the hub with the

splines in the sprocket meshing with the splines on

the hub and push the sprocket on as far as possible

by hand.

group and extend the ram to its limit with the pump

group.

(d) Assemble head (1) to cylinder group.

(e) Install adapter (3) onto the sprocket

shaft.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |