|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b. Cleaning. Clean all components in cleaning

solvent (Fed. Spec. P-D-680). Dry with clean, lint-

free cloths.

c. Inspection and Repair.

(1) Inspect the housing for nicks, chips,

cracks, weld damage and other damage. Repair or

replace if necessary.

(2) Inspect the ring gear for damaged or

missing teeth. Replace if defective.

(3) Check t h e flywheel housing runout

( s u b p a r a d) and flywheel runout (subpara e ) .

Repair or replace as necessary.

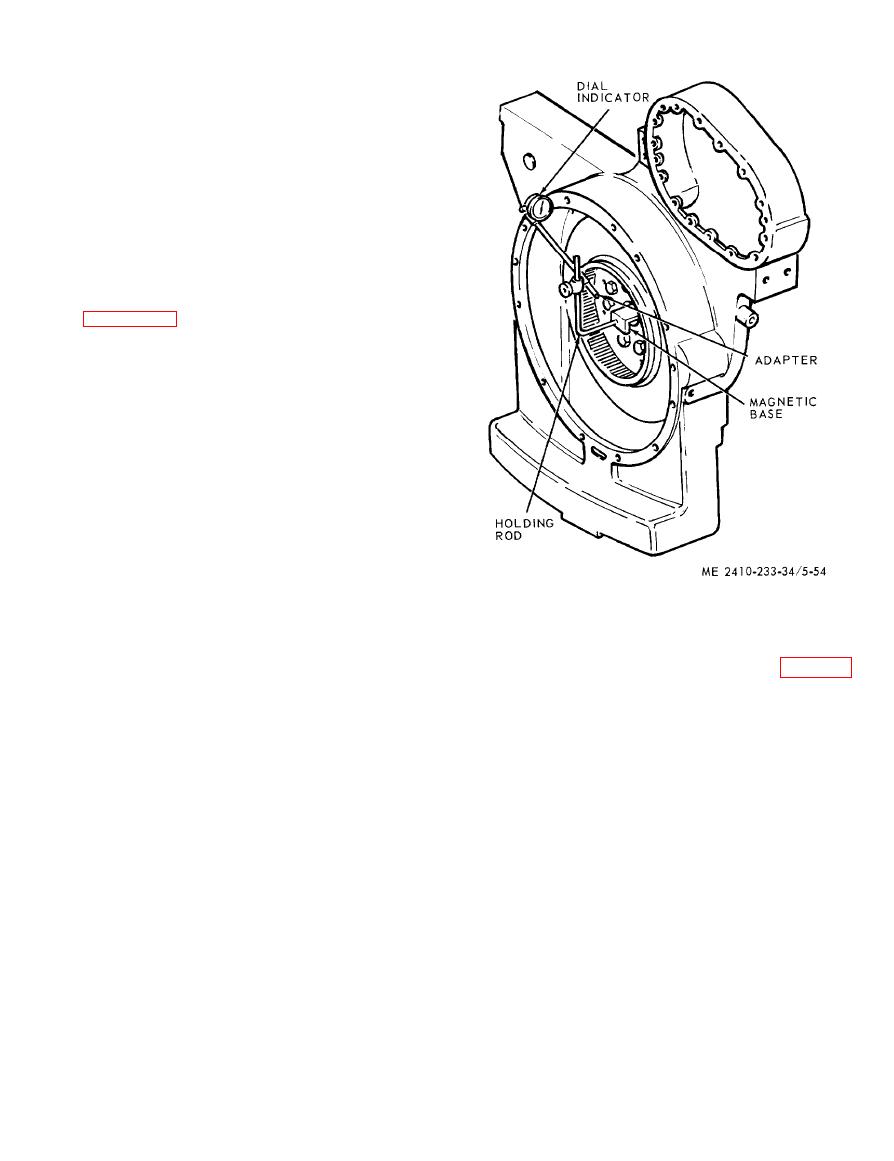

d. Checking Flywheel Housing Runout. Mount

a dial indicator to the flywheel housing as shown in

inch.

e. Checking Flywheel Runout. Mount a dial

indicator to the flywheel bore as shown in figure 5-

55 and check the runout. Total runout must not

exceed 0.006 inch.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |